This lovely 72w19 Singer Hemstitcher (circa 1945) has caused me all kinds of grief this month.

I have had a persistent problem with this machine every since I purchased it 4 years ago. The left needle thread has a tendency to break, almost randomly. I can stitch some distance, it will start skipping and then get cut by either the needles or the piercer. I have played around with various settings and adjustments continuously over all this time. Sometimes I can improve it, other times it becomes worse. Despite all these adjustments, the right needle continues to behave as it should and the left will not.

One day, I noticed that the piercer holder was loose. I could wiggle it with my finger. This led to me over tightening the piercer holder screw and breaking it. This screw is a size #6 and some of the screw was stuck in the machine. How to get it out?

It would be easy to say I am not a sewing machine mechanic. I have done some basic tuning up on regular sewing machines. Set the timing on both of my sewing machines. Cleaned, oiled, lubed. But that is about it. Armed with my 72w19 manual, I set out to fix my machine, extract that screw and get to the bottom of the thread breakage problem. The engineers who designed this machine and most mechanics who worked on these are all gone now. Those that are left are hobbyists, for the most part. Some are very good, but too far away to consult. Other mechanics rarely work on or understand these machines.

Even with the manual, there are gaps of knowledge. Perhaps later I will post a little about the history of these machines. One thing I did learn is that the ladies who purchased these machines attended a training and certification class so they could adjust them on their own. I am sure they picked up all kinds of information never written in the manual.

So back to the broken screw. Nothing could happen until that screw was extracted and replaced (and luckily I did find a replacement).

Assemble some basic tools:

1. Drill (variable speed, set on slowest setting)

2. Very small metal cutting drill bits (like 5/64")

3. Punch

4. Extractors and/or left hand drill bits

5. A steady hand.

Step 1

Use an auto centering punch to punch a pilot hole into the broken screw. There are different sizes and shapes of punches. I found one that is about the size of an ink pen. You press down on it and an internal spring forces the punch. A very nifty and useful gadget for small spaces (also expensive uni-tasker). You may need to do several punches because the surface of the broken screw will probably be uneven. This punch is critical so that the drill with a metal cutting bit doesn't float around.

Step 2

Using the drill with the regular metal cutting bit, drill a hole in the center of the broken screw. Make sure the drill is on a slow speed setting. In my case, I could drill all the way through the center of the screw to the other side and not risk damaging other components. Even so, drill just far enough to be able insert a slightly larger extractor or left hand drill bit. Stop every so often to clean out the hole and to let the drill bit cool off. The drill bit may dull quickly, so be prepared to replace it.

Step 3

If the screw is not jammed too tightly into the machine, you may be able to insert the extractor and turn the screw out by hand. This is what I ended up doing in my case. If you need more power, use the drill but be sure to reverse the direction of the drill.

And here is the result. You can see how small that broken screw bit was and why I was so nervous about it.

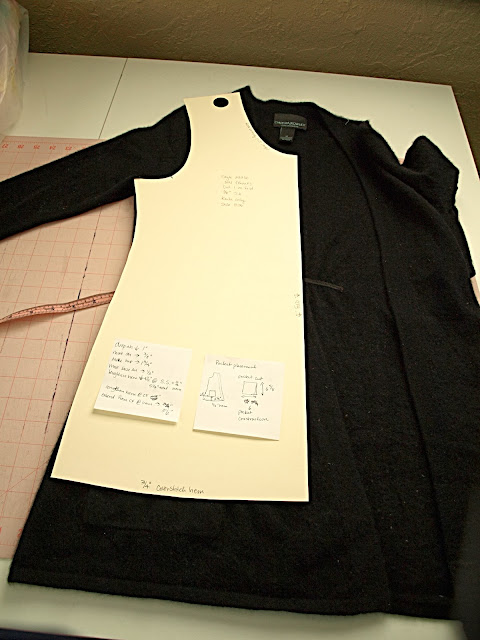

With the broken screw removed and a new one inserted, I once again began to check all the possible adjustments. In this I discovered more lose screws. There were lose screws on the piercer bar, and underneath the bobbin. Cleaned more lint and gunk out of areas I rarely clean. Oiled every moving part. Adjusted the vibration (zig-zag), pitmans, levers, etc. I could definitely say I have learned a lot by over adjusting some part and seeing what would happen (very carefully of course). I think I may have zeroed in on the vibration setting as the sources of the skipping as the left needle only skips on the inside vibration.

And then the piercer snapped in half the other day. I can't figure out how or why. Did I have it set too low in the machine? Maybe it was just worn out and over abused?

Thankfully, replacement piercers can still be found. Though they are very expensive. I bought two, just in case this happens again. Hopefully not.