I started knitting the sleeves a couple of weeks ago. The instructions for the sleeves, like the body, are dependent on the size. This makes sense because the lace pattern needs to be adapted for each size in order to work. The sleeves continue the all over lace pattern in order to seamlessly blend with the body. I had to read the instructions several times before I completely understood what was supposed to happen.

I am knitting the medium size. I followed the instructions exactly (I think) and this is what I ended up with.

For the medium size the pattern is written so that the lace pattern is repeated except for the underarm area. In this area you maintain stockinette stitches until the sleeve increases are completed. Then you start chart F for the length of the sleeve. I knew that if I saw this every time I wore it, it would drive me crazy. I'm not sure if I did something wrong, but this does not seem right.

There is a sleeve increase chart, but it is not used for the medium size. I debated ripping out what I had done and restarting with the sleeve increase chart, but I wasn't sure I really wanted an all lace sleeve. Instead I decided to center just one repeat of the lace down the center of the sleeve and do the rest in stockinette. I think it might work better with the sleeve cap decreases.

Showing posts with label Personal Projects. Show all posts

Showing posts with label Personal Projects. Show all posts

January 15, 2014

December 11, 2013

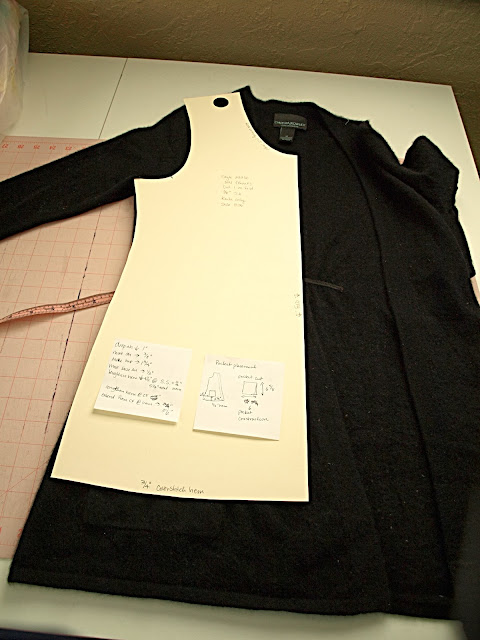

Adapting a block pattern into something else pt. 7 : Pattern modifications

Have you ever had a project bug you? I had my first sample hanging in the Design Loft almost taunting me. Originally I wanted a neckband on my cardigan. Then during construction, I changed to a rolled fabric edge along the neckline. The longer I stared at it, the less I liked it. Still unsure how a folded neckband would look, I whipped up a small sample, and what do you know? It worked just fine. It could be improved with a bit of interfacing, but not too bad.

So I pulled out the seam ripper and set to work. In addition, I removed some of the extra ease I had previously added for a closer fit.

You'll notice there are still a few minor adjustments that need to be made. The sleeves are too long. Yep, I over compensated there. The shoulder needs to be brought back up. And the back neckline needs to be raised. Despite all that, I am fairly pleased with the results. This is the style of cardigan that I really like. It looks sloppy in the photo because I used a rayon/poly jersey knit that is just too lightweight and drapey for the style. The next version will be even better. And yes I do plan to wear this, even in public. It is very, very comfortable.

November 13, 2013

Recovering Shoes - a step by step how to guide

Now that Halloween is over I can breathe for just a moment. My girls were Tinker Bell and Periwinkle based from Disney's movie Secret of the Wings. I was super excited for the request and the chance to make wings again, cause let's be honest, little fairies are just cute. The movie takes place in winter fairyland which is a bonus for staying warm while trick or treating. As part of their designs, I needed shoes that matched their outfits and is the focus of my post today. Tinker Bell wears boots and Periwinkle wears slip-on style slippers. I pulled shoes from the girls' closet according to overall shape and ones that would be easy to sew through, so no leather.

I learned to recover shoes in grad school and was taught to actual separate the sole from the main part of the shoe, not completely but enough to stuff about 1/2" or so of fabric into, and gluing everything back together with Barge cement. This method is a permanent change and I wanted to undo what I was doing.

This is the shoe before:

The fabric used for this project was stretch velour. I placed it on the shoe with the greatest stretch running from side to side. (If you are using a woven fabric then you will need to use the fabric on the bias).

I used a lot of pins and stabbed them straight in the shoe, right above the rubber sole.

After the fabric was draped and pinned in place, I trimmed off excess fabric leaving about 3/8" to turn under.

Here, I turned the seam allowance and repinned.

Ready to sew.

A curved needle would have been nice at this point but I made it work.

All finished except the puff ball.

I learned to recover shoes in grad school and was taught to actual separate the sole from the main part of the shoe, not completely but enough to stuff about 1/2" or so of fabric into, and gluing everything back together with Barge cement. This method is a permanent change and I wanted to undo what I was doing.

This is the shoe before:

The fabric used for this project was stretch velour. I placed it on the shoe with the greatest stretch running from side to side. (If you are using a woven fabric then you will need to use the fabric on the bias).

I used a lot of pins and stabbed them straight in the shoe, right above the rubber sole.

After the fabric was draped and pinned in place, I trimmed off excess fabric leaving about 3/8" to turn under.

Here, I turned the seam allowance and repinned.

Ready to sew.

A curved needle would have been nice at this point but I made it work.

All finished except the puff ball.

I added puff balls and fur trim.

|

| The fairies exploring the outdoors. |

October 09, 2013

Adapting a block pattern into something else pt. 1 : Noting changes for the new style

A block pattern is a sewing pattern that has been proven. It is a pattern that has been trued, perfected and finished with seam allowances. The pattern has been sewn up and tested for fit. In other words, a block pattern just works. A block pattern becomes a part of a pattern file which can be used to make other patterns.

In the industry we rarely draft from scratch. Instead we modify existing patterns (or blocks) into something else. Some pattern making gurus talk about using slopers. Slopers are basic patterns drafted from body measurements and do not have seam allowances. Industry level pattern makers use block patterns, with seam allowances on, to make patterns for new styles*. It saves time.

It's easier than you might think to do this and this is just one example. I'm sure other pattern makers have their own procedures. My own procedures adapt to whatever it is I'm working on and whether I'm using CAD or traditional methods.

The problem:

I have this much loved cashmere sweater jacket. I snagged it off a sales rack a couple of years ago and I absolutely love the cut and fit. You know, the perfect layering piece, warm and soft for those cool days. I usually clean it by running it through the dryer using a Dryel kit. This last time was a disaster as I had left a piece of chocolate in a pocket. Chocolate ended up all over the sweater and everything else. So, I decided to run it through the hand wash cycle on my washer. That was a mistake. While the chocolate did come out, the sweater shrank. It shrunk just enough that I'm not sure I can wear it anymore. It made me very sad. And yes, I know better. I should have hand washed it.

The solution:

I always said that once this sweater was in pieces, I would make up a pattern to make a new one. So here it is. I recently finished up my t-shirt pattern, a block pattern ready to go. I began by carefully laying out the sweater and positioning the front t-shirt pattern on top. I then used scraps of paper to note the differences between the sweater and the pattern. You can see my notes in the picture above.

The notes** usually say something like: Move SH pt out 1/2" (left arrow) ; or Extend hem (down arrow) 3 inches. These notes are sometimes accompanied with drawings as needed. If I was working in CAD, I would just mentally note the differences and make the changes as as I went along. Since I'm drafting with pencil and paper, the notes are essential.

The next step is to trace off the t-shirt pattern and start applying the changes. More on that later.

*There are a lot of pattern making myths out there. I'm trying to keep this blog entry very focused but I'm happy to answer pattern making questions and myths in future posts. Please leave your question or comment below.

**These notes eventually find their way to my pattern piece catalog. I assign a pattern piece number, note the style/pattern piece that the new piece came from, and then tell what changes were applied and any other relevant details. Blank forms for managing patterns are available in my Pattern Making bundle or in the book with complete instructions.

September 16, 2013

Organizing my workspace : Storing patterns cut in tag board

Well over a year ago I had made the final adjustments to my t-shirt pattern. I usually draft my first patterns on medical examination paper

Pieces cut in tag board are put on pattern hooks and then on racks. I prefer punching a hole in the pattern with a smaller hole punch so I can use book rings. The book rings are used to hang all the pieces of a style together but make it easier to remove one piece from the collection. The pattern hooks can be looped around the book ring and then hung on a rack.

*There are different work flows for pattern making. This is mine. Some professional pattern makers do all of their pattern making directly on oak tag and some are CAD only. Also, I do things a little differently in my home studio versus work. For example, the t-shirt pattern pieces are cutout in half because I place the piece on the fold at home. This would not happen in a factory. Generally, a production ready pattern would be the full piece (left and right sides) and not placed on a fold. It's not always so simple though. The pattern pieces are created to meet the specs of the fabric and production facility so variations may exist.

June 30, 2013

Knitting: Myrtle Cardigan pt. 2

This is my progress so far - 2 repeats done. I did the first repeat about 5 times. Now that I'm further along it is much easier to read the lace and catch mistakes quicker.

A few notes on the pattern.

1. Row 1 of the charts is read left-to-right, which is opposite of normal chart reading. Because of this, I follow the written out instruction for charts A and B.

2. The "map" for the size I'm knitting up is read right-to-left on the knit rows and left-to-right on purl rows. This is one of the things that caused me to rip out and redo that first repeat.

3. After completing a section (the stitches between markers) I stop and count the stitches. After ripping out and re-doing that first repeat so many times, I learned that counting after each section saves a lot of ripping.

A few notes on the pattern.

1. Row 1 of the charts is read left-to-right, which is opposite of normal chart reading. Because of this, I follow the written out instruction for charts A and B.

2. The "map" for the size I'm knitting up is read right-to-left on the knit rows and left-to-right on purl rows. This is one of the things that caused me to rip out and redo that first repeat.

3. After completing a section (the stitches between markers) I stop and count the stitches. After ripping out and re-doing that first repeat so many times, I learned that counting after each section saves a lot of ripping.

May 21, 2013

I Love Knits! : A guide to buying knit fabrics online

If you were to walk into my sewing studio, you will notice two things. One, I must have kids because it looks like a 2 year old has been in the vicinity and secondly, I have a large stash of knit fabric. I love knits. It is the main fabric of choice I have been buying lately. Back in 2009, I started making clothes for my first daughter and was introduced to Ottobre sewing magazines in my quest to find good children's sewing patterns. (Some other patterns I have used are Studio Tantrum and Roos - out of print). Many of the patterns in Ottobre are for knits.

When I first started working with knits, it was rather difficult to find cute knit fabric but now with the increase in demand many online vendors carry a variety of knits, which makes shopping much more enjoyable. (see my list at the end for some of my favorites).

I have learned several things along the way when working with knits:

I seldom find good knits locally but do get lucky on occasion. Most of my purchases are online and some vendors send swatches for free. Price is not always a factor. I few years ago, a pattern/fabric designer launched a knit line and charged a pretty penny for it. I felt at the time it was more than I would spend especially since I didn't know what the quality was like. The prints were cute and a number of people I know bought them. Well, it had a horrible shrink factor of 10-12%. I believe this problem has been corrected by the manufacturer since I have noticed the online vendors no longer state the shrinkage rate. I have bought cheap and still do but there is the risk of the fabric becoming piley and looking worn out quicker.

Stretch will impact the fit and choice of pattern. I will ask myself how much stretch does the fabric have and does it go back to the original shape and size afterwards. To find out stretch percentage, mark off 4 inches across (in the direction of the greatest stretch), then against a ruler hold down one side at the 0" mark while pulling until the fabric starts to resist, note how far it stretched. Let's say it stretched to 6", making it 2" longer. Now comes the math part (X/Y) x 100 = percentage of stretch. X = the number of inches stretched, here it is 2". Y = the base inches used, 4". 2 divide by 4 times 100 = 50%. If the fabric goes back to the original size/shape, great. If not I will make sure to use that fabric with a style that doesn't need retention, nothing close fitting.

Pick an appropriate pattern for your fabric or know how to adjust to make it work. Last year, I made a dance costume which had a leotard under-structure. The leotard was made from a 4-way stretch miliskin and the attached over dress was made from a 2 way stretch metallic. The pattern for the overdress was based off of the leotard but had to be adjusted in both width and length. I highly recommend reading www.patternschool.com blog authored by Stuart Anderson, a stretch-wear pattern maker. He teaches the mechanics of stretch, fit and pattern making. And quite frankly, the best information I have found on working with knits.

Besides making knitwear for my girls, I have been making t-shirts for myself. Lately, I am liking the looser blousier styles especially since I need to lose 20 lbs. of baby weight. My most recent shirt I made used a ribbed pointelle knit I found in the remnant section of the local chain fabric store. It was just under a yard and I probably paid less than $2.

The fabric is very soft and drapey. I looked through all my patterns and just couldn't find one I liked so I draped it and used an old shirt of mine as a pattern for the neckline. I used the actual fabric to drape in so, when it came time to take it off the mannequin I thread marked the seam allowances instead of using a marking pen.

I stabilized the shoulder line which is needed in knits because this is one area that can stretch out of shape. Instead of buying stay tape, I make my own using either lightweight fusible woven or fusible tricot/knit interfacing, cut at 3/8" wide. If using the knit fusible, I cut the length in the direction of least amount of stretch.

I usually sew my seams with a narrow zigzag and then serge together the edges to finish it. I got used to doing it this way because my serger is an industrial 5 stitch machine and has to be threaded in a three thread configuration for knits. So, I sew the seam first on the regular machine for strength and durability. My regular machine does have a stretch stitch but I don't care for it. It is hard to unpick if I make a mistake, so narrow zig zag it is. I have recently acquired a domestic four thread serger which I could use to seam and finish all at once, but I have it set up for roll hems and too lazy to change it back.

For hemming, I use a twin needle for stretch on a standard sewing machine. I don't own a coverstitch machine and have felt the expense not necessary for the amount of knit sewing I do. That being said, the twin needle works really well for t-shirts and clothing that don't need 100% stretch to function (100% stretch as required by swim wear and some athletic wear or dance wear). Twin needle hems will pop if the hem is over stretched. I have only had to fix a few hems from this happening. Sometimes for more stretch, I will use the triple zigzag, lightening or serpentine stitch (same stitch I just have heard it called all these names). Hemming (as well as bindings used for necklines or sleeves, will post about this later) is one area of sewing with knits that may need to have a sample sewn first before preceding with the actual garment. Below is a picture of a hem done with a twin needle. The fabric stretched out on me. There are some different methods of approach to fix this.

1. Hem using a coverstitch machine, though it can still stretch out.

2. Use the serpentine stitch to hem

3. Stabilize the fabric by placing a tear away stabilizer between the feed dogs and fabric.

4. Starch, lots of it. (just don't stretch the fabric while applying)

5. The lazy method, press with lots of steam and see what happens after hem is in place. (This works if the wonkiness is minimal and is what I used for this shirt).

6. Often times, a combination of any of the above.

Oh and lastly, I love working with knits because sewing projects work up really fast. T-shirts typically have 4-6 seams, not counting hems and the fabric is very forgiving.

Some online vendors I have bought knits from or just like to drool over:

Fabric.com

Print Knits Studio

Chez Ami

Girl Charlee

Gorgeous Fabric

Emma One Sock

Spandex World

Stretch House

When I first started working with knits, it was rather difficult to find cute knit fabric but now with the increase in demand many online vendors carry a variety of knits, which makes shopping much more enjoyable. (see my list at the end for some of my favorites).

I have learned several things along the way when working with knits:

Quality is worth the wait, research, and/or price.

I seldom find good knits locally but do get lucky on occasion. Most of my purchases are online and some vendors send swatches for free. Price is not always a factor. I few years ago, a pattern/fabric designer launched a knit line and charged a pretty penny for it. I felt at the time it was more than I would spend especially since I didn't know what the quality was like. The prints were cute and a number of people I know bought them. Well, it had a horrible shrink factor of 10-12%. I believe this problem has been corrected by the manufacturer since I have noticed the online vendors no longer state the shrinkage rate. I have bought cheap and still do but there is the risk of the fabric becoming piley and looking worn out quicker.

Analyze stretch.

Stretch will impact the fit and choice of pattern. I will ask myself how much stretch does the fabric have and does it go back to the original shape and size afterwards. To find out stretch percentage, mark off 4 inches across (in the direction of the greatest stretch), then against a ruler hold down one side at the 0" mark while pulling until the fabric starts to resist, note how far it stretched. Let's say it stretched to 6", making it 2" longer. Now comes the math part (X/Y) x 100 = percentage of stretch. X = the number of inches stretched, here it is 2". Y = the base inches used, 4". 2 divide by 4 times 100 = 50%. If the fabric goes back to the original size/shape, great. If not I will make sure to use that fabric with a style that doesn't need retention, nothing close fitting.

Pick appropriate pattern for fabric

Pick an appropriate pattern for your fabric or know how to adjust to make it work. Last year, I made a dance costume which had a leotard under-structure. The leotard was made from a 4-way stretch miliskin and the attached over dress was made from a 2 way stretch metallic. The pattern for the overdress was based off of the leotard but had to be adjusted in both width and length. I highly recommend reading www.patternschool.com blog authored by Stuart Anderson, a stretch-wear pattern maker. He teaches the mechanics of stretch, fit and pattern making. And quite frankly, the best information I have found on working with knits.

Create your own design

|

| Pointelle rib knit |

Besides making knitwear for my girls, I have been making t-shirts for myself. Lately, I am liking the looser blousier styles especially since I need to lose 20 lbs. of baby weight. My most recent shirt I made used a ribbed pointelle knit I found in the remnant section of the local chain fabric store. It was just under a yard and I probably paid less than $2.

|

| Playing with the idea of a boatneck, batwing sleeve, and belt. |

The fabric is very soft and drapey. I looked through all my patterns and just couldn't find one I liked so I draped it and used an old shirt of mine as a pattern for the neckline. I used the actual fabric to drape in so, when it came time to take it off the mannequin I thread marked the seam allowances instead of using a marking pen.

Since I didn't make a true mock-up, I checked the pattern in fabric. I doubled checked the shoulder length and side seams. I also did a quick and dirty fitting on myself to make sure the neck line laid properly. I have small shoulders and small back width from armscye to armscye.

|

| Stay tape on the back shoulder seam. |

I stabilized the shoulder line which is needed in knits because this is one area that can stretch out of shape. Instead of buying stay tape, I make my own using either lightweight fusible woven or fusible tricot/knit interfacing, cut at 3/8" wide. If using the knit fusible, I cut the length in the direction of least amount of stretch.

I usually sew my seams with a narrow zigzag and then serge together the edges to finish it. I got used to doing it this way because my serger is an industrial 5 stitch machine and has to be threaded in a three thread configuration for knits. So, I sew the seam first on the regular machine for strength and durability. My regular machine does have a stretch stitch but I don't care for it. It is hard to unpick if I make a mistake, so narrow zig zag it is. I have recently acquired a domestic four thread serger which I could use to seam and finish all at once, but I have it set up for roll hems and too lazy to change it back.

Hemming knits

For hemming, I use a twin needle for stretch on a standard sewing machine. I don't own a coverstitch machine and have felt the expense not necessary for the amount of knit sewing I do. That being said, the twin needle works really well for t-shirts and clothing that don't need 100% stretch to function (100% stretch as required by swim wear and some athletic wear or dance wear). Twin needle hems will pop if the hem is over stretched. I have only had to fix a few hems from this happening. Sometimes for more stretch, I will use the triple zigzag, lightening or serpentine stitch (same stitch I just have heard it called all these names). Hemming (as well as bindings used for necklines or sleeves, will post about this later) is one area of sewing with knits that may need to have a sample sewn first before preceding with the actual garment. Below is a picture of a hem done with a twin needle. The fabric stretched out on me. There are some different methods of approach to fix this.

|

| Before pressing |

2. Use the serpentine stitch to hem

3. Stabilize the fabric by placing a tear away stabilizer between the feed dogs and fabric.

4. Starch, lots of it. (just don't stretch the fabric while applying)

5. The lazy method, press with lots of steam and see what happens after hem is in place. (This works if the wonkiness is minimal and is what I used for this shirt).

6. Often times, a combination of any of the above.

|

| After pressing |

|

| Neckline using same twin needle. |

|

| Me in the finished shirt (sorry for the composition my 3.5 year old took the photo) |

Some online vendors I have bought knits from or just like to drool over:

Fabric.com

Print Knits Studio

Chez Ami

Girl Charlee

Gorgeous Fabric

Emma One Sock

Spandex World

Stretch House

Knitting: Myrtle cardigan pt. 1

I started a new ambitious project. The Myrtle cardigan has fairly good reviews on Ravelry, but underneath all that are subtle negatives. Some Ravelers have been downright vicious. I did fall in love with the all over lace pattern and I'm a sucker for a pretty cardigan. Even so, I was a bit nervous to start this.

One of the negatives on the pattern is the charts. The charts are not done correctly. Despite that, I can see how and why the pattern designer arranged the pattern as she did and there is a bit of genius behind it. In order to accommodate more than one size the pattern has to be changed for each size. So she created a roadmap of sorts with various charts for each size. It does work out well, but it's confusing at first. In fact, I spent a lot of time swatching and studying the pattern instructions. And then I read through the notes of other Ravelers to see what they did to make it easier. One simple help was to cut out the map for the size I am knitting and tape it to the chart pages so I wouldn't have to flip back and forth between so many pages. I'm using lots of markers and life lines.

Anyway, this is being knit in Knit Picks Stroll in Sapphire Heather on US 6.

I'm well into the first repeat and so far it is going pretty well. Fingers crossed as I progress.

One of the negatives on the pattern is the charts. The charts are not done correctly. Despite that, I can see how and why the pattern designer arranged the pattern as she did and there is a bit of genius behind it. In order to accommodate more than one size the pattern has to be changed for each size. So she created a roadmap of sorts with various charts for each size. It does work out well, but it's confusing at first. In fact, I spent a lot of time swatching and studying the pattern instructions. And then I read through the notes of other Ravelers to see what they did to make it easier. One simple help was to cut out the map for the size I am knitting and tape it to the chart pages so I wouldn't have to flip back and forth between so many pages. I'm using lots of markers and life lines.

Anyway, this is being knit in Knit Picks Stroll in Sapphire Heather on US 6.

I'm well into the first repeat and so far it is going pretty well. Fingers crossed as I progress.

May 07, 2013

Stuffed Toy Floor Bag

My kids stuff toy collection is getting out of control, mostly due to grandparents but we are just as guilty. And since they are young, I have all their toys in the family room so I can watch them from the kitchen and the pile was becoming unsightly, overflowing their corner. One evening while on Pinterest, I came across an idea to use a bean bag as storage for soft toys. I also found a company that makes a bag but charges more than I wanted to spend. I mean it is just a giant bag.

My version is a giant floor bag, large enough for 2-3 little ones to sit on.

Diameter of top and bottom circle pieces is 36". Side panel (in grey) measures 15"x 120".

My version is a giant floor bag, large enough for 2-3 little ones to sit on.

|

| The girls love it. |

Diameter of top and bottom circle pieces is 36". Side panel (in grey) measures 15"x 120".

|

| Fabric is a double sided fur fleece. |

I cut a 24" diameter inner circle in the top to create a mesh fabric window and zipper opening. The mesh fabric is an old laundry bag but you can buy mesh fabric like this from Seattle Fabrics. I used the small inner circle as a pattern for the mesh window adding 1" more for seam allowance.

A 1/2" binding strip of sheer tricot was applied to the cut edge of the mesh so one side of the zipper could be sewn on to it. The fur fleece was overlapped to finish the other side of the zipper.

February 18, 2013

Knitting - Isobel scarf

I finished spinning this yarn back in August. It's been waiting for me to decide what to do with it. A lacy scarf was what I wanted to make, but I also wanted to show off it's handspun goodness.

I tried 2 other patterns and finally settled on the Isobel. I love how the scarf turned out. It shows off the yarn well and is lacy and pretty. There is a subtle striping from the yarn because it is hand-dyed. But I don't really care, and it's not all that noticeable.

I tried 2 other patterns and finally settled on the Isobel. I love how the scarf turned out. It shows off the yarn well and is lacy and pretty. There is a subtle striping from the yarn because it is hand-dyed. But I don't really care, and it's not all that noticeable.

January 04, 2013

Review: Simple Modern Sewing pt. 1

Simple Modern Sewing one of the new how-to sew books at my library. I was excited to review this because Japanese sewing books have a reputation for precision and design that elevate the average sewing book. The Pattern Magic

This book is written by Shufu To Seikatsu Sha. The photography and styling of the designs really grabbed my attention. I personally found the designs very appealing and in this case something that I would actually make and wear. In comparison, I did not find any of the designs in the books I reviewed previously inspiring enough to put in the work necessary to make them up. The book consists of 8 simple patterns that can be used to create 25 garments. Each grouping of patterns can be mixed and matched interchangeably to create the different styles.

The book is divided up into three general sections. The first is the photography/inspiration section that shows each of the style variations. The second is general pattern and sewing instruction. The third contains detailed cutting and sewing instruction for each style variation. This includes a pattern layout, diagrams, and a list of sewing instructions.

The styles in the book are sized for the average Japanese woman. The average American woman may find some of the styles a bit on the small side. Some of the styles are intended to have a lot of wearing ease, so the largest size may fit some American women anyway. There is a size chart and finished measurements for each style, which helped me determine the correct size to trace.

Overall I really like the styles in this book. I selected the wrap blouse, shown on the front cover to sew up as a test for the dress. The biggest downfall of the book is the pattern sheet. It is nice to see the patterns are printed on sturdy white paper rather than tissue paper. But the pattern sheet is a dizzying array of overlapping pattern pieces in multiple sizes in solid black lines. All the patterns and all the sizes are solid black lines. Burda patterns are similar, but they are much easier to sort out. Each style is a different color and the sizes are differentiated by different line types.

To finish up part 1 of the review, the book is inspiring and lovely to look at. The general sewing information and detailed sewing information appear to be adequate for sewists who have some experience. The cutting diagrams and pattern prep require a bit of work. Because of the difficult pattern sheets, I don't know that I can recommend the book for beginning sewists. The styles are simple enough that one could find similar patterns from the Big 4 without the hassle of interpreting the pattern sheet.

Anyway, I've traced off the blouse and dress pieces and begun the pattern checking process. So far I've spent maybe 4 hours just in prep work. Updates as I work my through it.

January 02, 2013

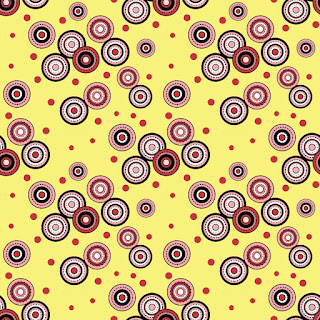

Creating fabric repeats with Gimp

This tutorial, such as it is, could easily be called How to create seamless tile repeats with Gimp. If you do a google search for Gimp seamless, you will find lots of tutorials. Because of that, I won't do a detailed tutorial. This is a follow-up of my review of A Field Guide to Fabric Design.

The main difficulty I had with Gimp and creating a seamless repeat is a problem filter*.

Don't use this filter:

Filters - Map - Make Seamless

The resulting image doesn't make an attractive repeat. It overlaps the repeat with transparencies.

Instead the offset tool, which is similar to Photoshop, is located:

Layers - Transform - Offset

Finding this tool made all the difference. Conversely, I played around with the select tool and moving layers around to accomplish the same thing. The offset tool works best with the design repeat located far from the image borders and in the center of your image. For more complex repeats, manually selecting parts of the image, copy-paste into a new image and moving them in layers works better.**

I started my experiment with a vector line drawing made in Inkscape and exported as a PNG file.

Next I pulled the line drawing into Gimp, added a background color, and then applied the offset tool. After that, I filled in the blank areas. Again, detailed instructions in the book for a simple repeat and more complex repeats.

Gimp has a handy tool that allows you to test your repeat located here.

Filters - Map - Small tiles

This is how my repeat looks now.

The repeat could use a bit more work, but I think you get the idea. A Field Guide to Fabric Design has information on how to improve your repeat and also how to create a whole collection around this one design.

Of course, the real challenge is matching up the colors with Pantone.

* I tried to take screenshots of all of this but my print screen button wasn't cooperating.

** One of these days I may create a tutorial for this, but it is a bit more involved. My trial video demo took about 20 minutes.

The main difficulty I had with Gimp and creating a seamless repeat is a problem filter*.

Don't use this filter:

Filters - Map - Make Seamless

The resulting image doesn't make an attractive repeat. It overlaps the repeat with transparencies.

Instead the offset tool, which is similar to Photoshop, is located:

Layers - Transform - Offset

Finding this tool made all the difference. Conversely, I played around with the select tool and moving layers around to accomplish the same thing. The offset tool works best with the design repeat located far from the image borders and in the center of your image. For more complex repeats, manually selecting parts of the image, copy-paste into a new image and moving them in layers works better.**

I started my experiment with a vector line drawing made in Inkscape and exported as a PNG file.

Next I pulled the line drawing into Gimp, added a background color, and then applied the offset tool. After that, I filled in the blank areas. Again, detailed instructions in the book for a simple repeat and more complex repeats.

Gimp has a handy tool that allows you to test your repeat located here.

Filters - Map - Small tiles

This is how my repeat looks now.

The repeat could use a bit more work, but I think you get the idea. A Field Guide to Fabric Design has information on how to improve your repeat and also how to create a whole collection around this one design.

Of course, the real challenge is matching up the colors with Pantone.

* I tried to take screenshots of all of this but my print screen button wasn't cooperating.

** One of these days I may create a tutorial for this, but it is a bit more involved. My trial video demo took about 20 minutes.

January 09, 2012

T-shirt pattern quest pt. 4 : Analysis of fit and construction

Here are the results of my first and second pattern test. I had enough fabric to make two shirts. Each shirt revealed problems with my construction and fit. I had added about 1" of extra wearing ease to shirt 1 and that was reduced to 1/2" of extra ease in shirt 2. The pattern was designed with 3/8" seam allowances. This allowed for an 1/8" cut off on the seam edges so that the seams finish at 1/4". I had difficulty in shirt 1 maintaining that cut off allowance, improving on the second.

One thing I did not notice is that this fabric is directional. With napped fabrics, the fabric can look darker or lighter depending on which direction the fabric lays. This interlock is not napped but it definitely looks different in different directions. I had switched the direction of the sleeves on shirt 2 and so there is a color variation. It is subtle and hardly noticeable except in certain light.

Finally, there is an issue with the fit of the armhole, which is just a bit too tight. This creates unsightly wrinkles in the underarm area. I guess I never noticed on the original shirt, but the problem exists there too. So, a bit of adjustment has to happen. I need to lower the armhole a bit and scoop out the front. This means the sleeve will need a bit of adjustment as well. The armholes will no longer be symmetrical front to back, which is how it should be. Anyway, more on that as progress is made.

The shirts are fine and comfortable enough to wear, but a modeled shot may or may not appear on the blog

December 15, 2011

T-shirt pattern quest pt. 2 : Calculating the amount stretch in a knit fabric

Patterns for styles made out of a knit fabric need to include the amount of wearing ease for the desired fit. In some cases the wearing ease is actually negative ease. Negative ease means the pattern measurement is smaller than the actual corresponding body measurement. A good example of this would be yoga pants in which the pants stretch to fit a particular size. In some cases the pattern has positive wearing ease because the style is larger than the corresponding body measurements, such as an oversized sweatshirt. Determining how much to reduce a pattern for a desired type of fit requires first determining a knit fabrics stretch factor.

Note - My pattern is intended for knits that have already been pre-washed and shrunk from retail store knits. So no extra allowance is included for shrinkage.

At this point I needed to check the amount of stretch in this fabric. Fold the fabric so that you are not testing on the edge of the fabric. Place two pins 5 inches apart.

Pick up the fabric and hold the left pin in your left hand at the zero mark and then stretch the fabric as far as it will go with your right hand. Watch where the right pin stretches on the stretch ruler. In this case, my fabric stretches about 30%. Only stretch the fabric as far as it will reasonably go without overly stressing the fabric.

Let go of the fabric with your right hand and watch to see if the fabric returns to it's original position. Knits that do not return at all, have no recovery. In this case, my fabric returned to the 10% mark, which isn't great, but probably ok for a top.

I had forgotten, but this particular fabric is an interlock rather than a jersey. Interlocks do not stretch nearly as much as a jersey. I had originally planned on adding about 1 inch of extra wearing ease because I wanted a bit looser fit. Now I wonder if I should add a bit of extra? Once I work that out, I will modify my pattern and cut it out.

April 14, 2010

Crochet Dish Scrubbie and knit dishcloth

I have had a flare up of carpal tunnel and possibly arthritis. I know I am too young for the arthritis, but this flare up was different from years ago. Many years ago I found that knitting and crocheting actually helped my carpal tunnel. Of course it can actually make it worse if you do too much. It must be something about strengthening the muscles in your fingers and hands...

Anyway, I am working through my meager yarn stash and making practical stuff. First up is a dish scrubbie or tawashi. I love this and have made several. There are many different styles and I may try other versions.

I am also making dishcloths. I like the texture of this one.

The pattern is called Double Bump and is available as a free Ravelry download.

Anyway, I am working through my meager yarn stash and making practical stuff. First up is a dish scrubbie or tawashi. I love this and have made several. There are many different styles and I may try other versions.

I am also making dishcloths. I like the texture of this one.

The pattern is called Double Bump and is available as a free Ravelry download.

June 09, 2009

Correcting the fit of petal sleeves in a wedding dress pt. 1

I have been working on altering a wedding dress. It is, admittedly, a budget wedding dress available for less than $200 imported from China. I am by no means a wedding dress expert, so this little assignment is teaching me a lot about how wedding dresses are made today. There are some things about this dress that I found very interesting and innovative - things I have never seen before. And it is true, I haven't really looked at wedding dresses since my wedding many moons ago. In any event, dresses now have attached petticoats (I had to buy a separate one) and embedded, uh-hum, bust padding. On the other hand, there are some problems with this dress that clearly label it a budget dress, albeit a very pretty dress for the bride. And I should say the budget dresses available now are much prettier than they used to be. They have embroidery with beading, nicer fabrics, and that full, attached petticoat. Much fodder for future blog posts.

I'll show the nice features of the dress later. For now I will show show one of the problems. It is an annoying problem and one I was surprised to find. The dress has petal sleeves, which I have drafted before. I have even had this same problem show up. Can you spot the problem with the sleeves?

Even though this is on a hanger, the sleeves hang like this on the bride.

Even though this is on a hanger, the sleeves hang like this on the bride.

Here is the sleeve off the dress. I not only had to bring up the shoulders, but take the sleeves completely off to recut the armholes. The shoulders and armholes are part of a larger, but separate problem. This picture should give the problem away.

Here is the sleeve off the dress. I not only had to bring up the shoulders, but take the sleeves completely off to recut the armholes. The shoulders and armholes are part of a larger, but separate problem. This picture should give the problem away.

I'll show the nice features of the dress later. For now I will show show one of the problems. It is an annoying problem and one I was surprised to find. The dress has petal sleeves, which I have drafted before. I have even had this same problem show up. Can you spot the problem with the sleeves?

Even though this is on a hanger, the sleeves hang like this on the bride.

Even though this is on a hanger, the sleeves hang like this on the bride. Here is the sleeve off the dress. I not only had to bring up the shoulders, but take the sleeves completely off to recut the armholes. The shoulders and armholes are part of a larger, but separate problem. This picture should give the problem away.

Here is the sleeve off the dress. I not only had to bring up the shoulders, but take the sleeves completely off to recut the armholes. The shoulders and armholes are part of a larger, but separate problem. This picture should give the problem away.

Subscribe to:

Posts (Atom)