I admit that sometimes I make mistakes. A person reading my previous blog entry on a wedding care/content label pointed out some inaccuracies in how I wrote my suggested label. The FTC has some guidelines on how to write labels, both for content and care. I've read these instructions many times, but I sometimes need a refresher. Yes, it would be a good idea for anyone who has to write labels to read the instructions themselves rather than rely on a blog entry (or an anonymous commenter).*

Care instructions follow the general form:

Washing

Bleaching

Drying

Ironing

Warnings

If a dress truly cannot be dry cleaned, then the label should include that instruction. My label suggestion would be more accurate if I had included that instruction. I had also placed the bleaching instruction in the wrong order. Perhaps a better, more accurate, and perhaps correct label (changes in bold) would read:

100% Polyester

Do not dry clean.

Hand wash or

Spot clean in cold

water with mild

soap. Do not bleach.

Hang to dry.

Do not iron.

Made in China

RN12345 (<------ Made up)

---------------------

Avoid the use of

alcohol based products

such as hairspray,

perfume, etc., as these

may damage the dress.

The commenter also pointed out that if there is a reasonable basis for care instructions, then a manufacturer does not need to destroy a dress to prove it. I guess the question that must be determined is what is reasonable? In my opinion (and just for this commenter, this IS my opinion, for what it's worth), a new wedding dress manufacturer should destroy a few dresses to prove their labels. If you think something can be dry cleaned, you should be able to prove it. Same with any other care instructions. Over time, you may be able to reduce the type and amount of testing provided you do not change your component parts. This is probably the reason behind some of the testing requirements in the CPSIA. When you change a component (sometimes even from the same source), you have introduced a variable which may result in different testing guidelines.

I know wedding dresses are expensive, even the initial samples. Is it reasonable that every dress be tested to prove the care instructions? I am not sure every manufacturer goes to that extreme. But it is reasonable that a few have been. Testing a whole complete unit is the only way to test for compatibility of components. Testing a whole complete unit will tell you what a customer will experience. Wedding dresses have a lot of sentimental value and you wouldn't want a customer to have a dress ruined by poor or incorrect cleaning instructions. But this decision is best left to the manufacturer and the responsibility they are willing to bear if something were to go wrong.

As a manufacturer develops, it is reasonable to also test components. It is common for a manufacturer to use the same polyester satin in multiple styles and all they do is change up the trimming. In this case, the satin has probably been washed tested a few times and they know how it should be cleaned. But the trimming is different. In this case, I take some yardage, stitch the trim on and wash it (or dry clean it) - multiple times.

I can recall some concern I had about some flocked glitter on a chiffon. The glitter can fall off because the dry cleaning solvents will dissolve the glue. Washing by hand or machine can cause the glitter to fall off due to abrasion. So we tested various scenarios and came up with a reasonable basis for care. The same scenario can be applied to beads. Though I must say, based on my experience testing, some beads can be dry cleaned and some cannot. Some will fall apart even when hand washing. You won't know unless you test.

It is reasonable that a manufacturer has proof for the testing they recommend. I believe this includes documentation. You won't have documentation unless you test something. These days, I am not sure that a government regulator will appreciate your good intentions or your word without some kind of proof.

And finally, it is true that the CPSIA does not specifically mention wash testing (as I stated in my previous blog entry). It does imply that any testing be done by a certified 3rd party lab. When I worked various private label programs for Big Box stores, they required wash testing by an approved 3rd party testing lab. At that time we were able to negotiate creating an in-house wash testing program to save money. We were required to submit a copy of our test results with the 3rd party testing reports to the technical designers of the big box stores. In the days of CPSIA, I imagine this is no longer possible (I haven't worked on any private label programs in a while, so someone else who has will have to clarify this point). So while the law may not specifically mention wash testing by a certified lab, Big Box retailers might require it anyway. This is thus my reasoning for why I said what I said.

*When I wrote my original blog entry, the FTC site was down and had been down for a few weeks. My intention was to verify and correct my article and I didn't do that because I couldn't. It was one of those things that fell off my radar and I didn't get back to it. My apologies to anyone if I misled. I appreciate comments that politely correct me when I have misstated something. However, I won't print comments that are insulting and offensive.

Showing posts with label Wedding dress. Show all posts

Showing posts with label Wedding dress. Show all posts

February 04, 2010

July 07, 2009

Wedding Dress Care-Content Labeling

This article now has a follow-up blog entry with some corrections and additional opinions. Your comments are welcome, but hateful or spammy comments will be deleted.

As I was working on the alterations for this wedding dress, I wanted to see other dresses by this designer/maker. Perhaps the sleeve pattern shaping was intentional and not a mistake? Perhaps the problem is consistently found in other styles? I had no idea who the designer was, only where the dress was purchased. The dress was not in the store's web catalog and the only label in the dress was not helpful. The dress was missing a brand label and had no RN number. Further, the care instructions were rather bizarre/interesting (click on the picture for a closer view). I googled the style number and came up empty.

At a minimum, the dress should have had an RN number on the label. You can search an FTC database to find out the manufacturer of an apparel item. Wedding dress manufacturers/bridal shops have been fined in the past for failing to disclose or intentionally removing this information. Alterationists may remove the labels after purchase but should give them to the bride (links to come later as the FTC website was having problems when I wrote this).

The label states:

100% polyester

Do not dryclean

Spot clean ONLY

Use cold water and

mild soap

Made in China

See reverse for care

----------------------

Do not spray Alcohol

based product directly

on gown such as Perfume,

Hairspray....etc. This will

damage beadworks and

embroiderie designs made of

Rayon, Nylon, and other

synthetic materials.

I found the care instructions rather hilarious. How many of you spot cleaned your wedding dress with only cold water and mild soap? The fabrics themselves probably could be dry cleaned or even hand washed (though that may be more work). The beads will probably dissolve in the dry cleaning solvents, so thus the "do not dry clean" instructions. But, if you can find a reputable dry cleaner who will clean the dress and avoid the beads, then go ahead and have the dress dry cleaned. Otherwise, hand wash the dress. BTW, there were no further care instructions on the back of the label. Many wedding dresses are currently manufactured in China, which may explain the poorly written tag.

The extra instructions are interesting. I suppose it is possible that perfume or hairspray may damage the beads. Though the bride would probably need to be drenched in it before the beads dissolved. Sure would like to put those beads to the test....

The label should have been written to say:

100% Polyester

Hand wash or

Spot clean

in cold water with

mild soap. Hang to

dry. Do not bleach,

Do not iron.

Made in China

RN12345 ( ------ Made up)

---------------------

Avoid the use of

Alcohol based products

such as hairspray,

perfume, etc., as these

may damage the dress.

And of course, the care instructions should be thoroughly tested by the manufacturer. Good industry practice (and the government) dictate that a manufacturer should have a reasonable basis for the cleaning instructions. This means actual test data recorded and stored with the manufacturer. At this point in time, manufacturers (except children's clothing manufacturers) can do their own in-house wash testing. Children's clothing manufacturers will have to have it done by a certified laboratory. Wash testing is not specifically mentioned in the CPSIA, but it does imply that ANY testing will have to be done in a certified lab.

Labels:

Care/Content Tags,

Cleaning,

CPSC,

CPSIA,

Dry cleaning,

Fabric,

FTC,

Labels,

Testing,

Wash testing,

Wedding dress

July 06, 2009

Correcting the fit of petal sleeves in a wedding dress pt. 2

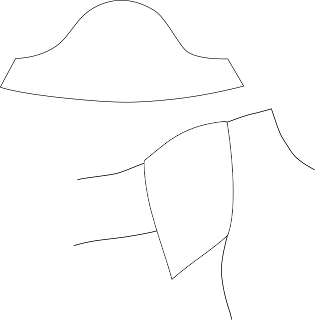

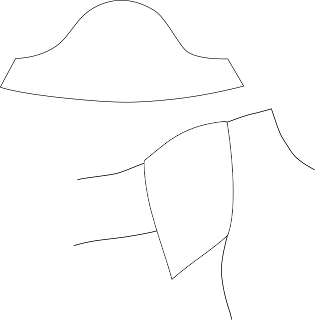

I finally had a chance to do up some line drawings to illustrate the problem with the petal sleeves of the wedding dress I recently altered. There are more pictures in the blog entry Petal Sleeves pt. 1.

The shape of the sleeve pattern adds a lot of extra material under the arm - creating almost a circular sleeve. The hem of the sleeve flapped around like wings. IMO, it wasn't very attractive. Even though the dress was a plus size dress, I can't imagine any woman wanting this style. I find it hard to believe the designer intended this either. I could be wrong since I am not familiar with wedding dress design. I do know that wedding dresses are designed to be easy to alter so perhaps the designer allowed for extra underarm width to accommodate the size of any upper arm. Even so, with the combination of removing excess shoulder height, recutting the armholes and sleeves, the alteration was not that easy. I dare say, it is either sloppy pattern making and/or grading. I would pin the source of the problem on grading from a size 6 all the way into a plus size. I (and Kathleen) have blogged about this many times (search for "Grading is not morphing" at Fashion-Incubator). Plus sizes should have their own patterns separate from Misses sizes. Trying to save time and effort by "grading" patterns from a size 6 up into the plus sizes leads to problems like this. Of course, I don't really know if this is exactly what happened. I would need to look at the whole size range and even the actual pattern pieces to know for sure.

This is what the pattern pieces and fit looked like on the bride before the alteration. The petal sleeve is a regular cap sleeve in the example below. You can see the extra width added at the hem of the sleeve and the wings it creates under the arm.

Below is the shape of the pattern after the alteration. I probably removed a good 1.5" from the sleeve hemline. The fit of the sleeve looked 100% better.

Now if the intent of the pattern maker was to allow the bride to be able to lift her arms for dancing, then it was added in the wrong place. A gusset should be added at the underarm - not the sleeve hemline.

The shape of the sleeve pattern adds a lot of extra material under the arm - creating almost a circular sleeve. The hem of the sleeve flapped around like wings. IMO, it wasn't very attractive. Even though the dress was a plus size dress, I can't imagine any woman wanting this style. I find it hard to believe the designer intended this either. I could be wrong since I am not familiar with wedding dress design. I do know that wedding dresses are designed to be easy to alter so perhaps the designer allowed for extra underarm width to accommodate the size of any upper arm. Even so, with the combination of removing excess shoulder height, recutting the armholes and sleeves, the alteration was not that easy. I dare say, it is either sloppy pattern making and/or grading. I would pin the source of the problem on grading from a size 6 all the way into a plus size. I (and Kathleen) have blogged about this many times (search for "Grading is not morphing" at Fashion-Incubator). Plus sizes should have their own patterns separate from Misses sizes. Trying to save time and effort by "grading" patterns from a size 6 up into the plus sizes leads to problems like this. Of course, I don't really know if this is exactly what happened. I would need to look at the whole size range and even the actual pattern pieces to know for sure.

This is what the pattern pieces and fit looked like on the bride before the alteration. The petal sleeve is a regular cap sleeve in the example below. You can see the extra width added at the hem of the sleeve and the wings it creates under the arm.

Below is the shape of the pattern after the alteration. I probably removed a good 1.5" from the sleeve hemline. The fit of the sleeve looked 100% better.

Now if the intent of the pattern maker was to allow the bride to be able to lift her arms for dancing, then it was added in the wrong place. A gusset should be added at the underarm - not the sleeve hemline.

Labels:

Adjustments,

Alterations,

Cap sleeve pattern,

Dresses,

Patternmaking,

Sleeve,

Wedding dress

July 02, 2009

Wedding Dress Alteration: The Whole Picture?

I don't think I posted pictures of the whole dress I recently altered. Here is the top with the alterations marked with pins. Recutting the armhole and adjusting the sleeves was probably the most difficult part of the alterations. The bride really needed a little bit taken in at the back, but that is one alteration I did not attempt. The zipper and lining would have to be ripped out and I had no time for that. The dress shop provided double sided tape to help keep things in place (maybe they knew how poor fitting this dress would be). I recommended the bride go ahead and use it for the gap-osis I would not be able to fix - though I did fix most of it.

Here is the skirt. Really, the simplest style of skirt to shorten if needed. Just make the tucks a bit deeper. I probably should have gone ahead and taken 1" off the bottom hem too, but I just advised the bride to buy some heels. The skirt is completely underlined with tulle to help give the skirt some shape and hold the draped tucks.

The wedding was this last week and the bride was absolutely radiant with joy. She looked lovely and no one was the wiser that a neophyte alterationist did the job. Maybe I will post a picture of the big day once I get the pictures off the camera.

Here is the skirt. Really, the simplest style of skirt to shorten if needed. Just make the tucks a bit deeper. I probably should have gone ahead and taken 1" off the bottom hem too, but I just advised the bride to buy some heels. The skirt is completely underlined with tulle to help give the skirt some shape and hold the draped tucks.

The wedding was this last week and the bride was absolutely radiant with joy. She looked lovely and no one was the wiser that a neophyte alterationist did the job. Maybe I will post a picture of the big day once I get the pictures off the camera.

Labels:

Alterations,

Dresses,

Patternmaking,

Sewing Techniques,

Sleeve,

Wedding dress

June 16, 2009

Wedding Dress Alteration: The Underlining

I expected to find boning in a size 18 wedding dress. I think I even put it in my dress, though the style didn't really need it. This dress doesn't have it at all. It does have the addition of padded bust cups - a feature I have not seen before (I would still recommend the bride wear a supportive bra anyway). The bodice and lining have been completely underlined with fusible. The outer fabric has a stiffer woven fusible and the lining has a softer knitted fusible. Click on the picture to get a better view of the inside of the dress. I am still debating on whether the dress should have boning or not. I think if the bride wears a body-shaping undergarment, it will help smooth out any bulges she doesn't want seen. Even so, it looks and fits pretty good in the waist area.

BTW, a common alteration in wedding dresses is to take it in some at the top of the princess line as it goes into the armhole. If this is indeed "common", it leads me to believe there is a grading or underlying pattern fit issue with wedding dress manufacturers. This alteration, plus taking it up in the shoulders, requires the alterationist to recut the armhole and sleeve (if a cap sleeve). A nasty set of alterations, IMO.

Labels:

Dresses,

Patternmaking,

Product Review,

Sewing Techniques,

Wedding dress

June 09, 2009

Correcting the fit of petal sleeves in a wedding dress pt. 1

I have been working on altering a wedding dress. It is, admittedly, a budget wedding dress available for less than $200 imported from China. I am by no means a wedding dress expert, so this little assignment is teaching me a lot about how wedding dresses are made today. There are some things about this dress that I found very interesting and innovative - things I have never seen before. And it is true, I haven't really looked at wedding dresses since my wedding many moons ago. In any event, dresses now have attached petticoats (I had to buy a separate one) and embedded, uh-hum, bust padding. On the other hand, there are some problems with this dress that clearly label it a budget dress, albeit a very pretty dress for the bride. And I should say the budget dresses available now are much prettier than they used to be. They have embroidery with beading, nicer fabrics, and that full, attached petticoat. Much fodder for future blog posts.

I'll show the nice features of the dress later. For now I will show show one of the problems. It is an annoying problem and one I was surprised to find. The dress has petal sleeves, which I have drafted before. I have even had this same problem show up. Can you spot the problem with the sleeves?

Even though this is on a hanger, the sleeves hang like this on the bride.

Even though this is on a hanger, the sleeves hang like this on the bride.

Here is the sleeve off the dress. I not only had to bring up the shoulders, but take the sleeves completely off to recut the armholes. The shoulders and armholes are part of a larger, but separate problem. This picture should give the problem away.

Here is the sleeve off the dress. I not only had to bring up the shoulders, but take the sleeves completely off to recut the armholes. The shoulders and armholes are part of a larger, but separate problem. This picture should give the problem away.

I'll show the nice features of the dress later. For now I will show show one of the problems. It is an annoying problem and one I was surprised to find. The dress has petal sleeves, which I have drafted before. I have even had this same problem show up. Can you spot the problem with the sleeves?

Even though this is on a hanger, the sleeves hang like this on the bride.

Even though this is on a hanger, the sleeves hang like this on the bride. Here is the sleeve off the dress. I not only had to bring up the shoulders, but take the sleeves completely off to recut the armholes. The shoulders and armholes are part of a larger, but separate problem. This picture should give the problem away.

Here is the sleeve off the dress. I not only had to bring up the shoulders, but take the sleeves completely off to recut the armholes. The shoulders and armholes are part of a larger, but separate problem. This picture should give the problem away.

Subscribe to:

Comments (Atom)