I admit that sometimes I make mistakes. A person reading my previous blog entry on a wedding care/content label pointed out some inaccuracies in how I wrote my suggested label. The FTC has some guidelines on how to write labels, both for content and care. I've read these instructions many times, but I sometimes need a refresher. Yes, it would be a good idea for anyone who has to write labels to read the instructions themselves rather than rely on a blog entry (or an anonymous commenter).*

Care instructions follow the general form:

Washing

Bleaching

Drying

Ironing

Warnings

If a dress truly cannot be dry cleaned, then the label should include that instruction. My label suggestion would be more accurate if I had included that instruction. I had also placed the bleaching instruction in the wrong order. Perhaps a better, more accurate, and perhaps correct label (changes in bold) would read:

100% Polyester

Do not dry clean.

Hand wash or

Spot clean in cold

water with mild

soap. Do not bleach.

Hang to dry.

Do not iron.

Made in China

RN12345 (<------ Made up)

---------------------

Avoid the use of

alcohol based products

such as hairspray,

perfume, etc., as these

may damage the dress.

The commenter also pointed out that if there is a reasonable basis for care instructions, then a manufacturer does not need to destroy a dress to prove it. I guess the question that must be determined is what is reasonable? In my opinion (and just for this commenter, this IS my opinion, for what it's worth), a new wedding dress manufacturer should destroy a few dresses to prove their labels. If you think something can be dry cleaned, you should be able to prove it. Same with any other care instructions. Over time, you may be able to reduce the type and amount of testing provided you do not change your component parts. This is probably the reason behind some of the testing requirements in the CPSIA. When you change a component (sometimes even from the same source), you have introduced a variable which may result in different testing guidelines.

I know wedding dresses are expensive, even the initial samples. Is it reasonable that every dress be tested to prove the care instructions? I am not sure every manufacturer goes to that extreme. But it is reasonable that a few have been. Testing a whole complete unit is the only way to test for compatibility of components. Testing a whole complete unit will tell you what a customer will experience. Wedding dresses have a lot of sentimental value and you wouldn't want a customer to have a dress ruined by poor or incorrect cleaning instructions. But this decision is best left to the manufacturer and the responsibility they are willing to bear if something were to go wrong.

As a manufacturer develops, it is reasonable to also test components. It is common for a manufacturer to use the same polyester satin in multiple styles and all they do is change up the trimming. In this case, the satin has probably been washed tested a few times and they know how it should be cleaned. But the trimming is different. In this case, I take some yardage, stitch the trim on and wash it (or dry clean it) - multiple times.

I can recall some concern I had about some flocked glitter on a chiffon. The glitter can fall off because the dry cleaning solvents will dissolve the glue. Washing by hand or machine can cause the glitter to fall off due to abrasion. So we tested various scenarios and came up with a reasonable basis for care. The same scenario can be applied to beads. Though I must say, based on my experience testing, some beads can be dry cleaned and some cannot. Some will fall apart even when hand washing. You won't know unless you test.

It is reasonable that a manufacturer has proof for the testing they recommend. I believe this includes documentation. You won't have documentation unless you test something. These days, I am not sure that a government regulator will appreciate your good intentions or your word without some kind of proof.

And finally, it is true that the CPSIA does not specifically mention wash testing (as I stated in my previous blog entry). It does imply that any testing be done by a certified 3rd party lab. When I worked various private label programs for Big Box stores, they required wash testing by an approved 3rd party testing lab. At that time we were able to negotiate creating an in-house wash testing program to save money. We were required to submit a copy of our test results with the 3rd party testing reports to the technical designers of the big box stores. In the days of CPSIA, I imagine this is no longer possible (I haven't worked on any private label programs in a while, so someone else who has will have to clarify this point). So while the law may not specifically mention wash testing by a certified lab, Big Box retailers might require it anyway. This is thus my reasoning for why I said what I said.

*When I wrote my original blog entry, the FTC site was down and had been down for a few weeks. My intention was to verify and correct my article and I didn't do that because I couldn't. It was one of those things that fell off my radar and I didn't get back to it. My apologies to anyone if I misled. I appreciate comments that politely correct me when I have misstated something. However, I won't print comments that are insulting and offensive.

Showing posts with label Care/Content Tags. Show all posts

Showing posts with label Care/Content Tags. Show all posts

February 04, 2010

January 17, 2010

Warning: Tagless labels in baby clothes and the CPSIA

My sister sent me an update on the problem. It appears that the re-formulated paints may include latex tainted paint, similar to silk screen paint. My niece had another reaction even worse than previous because her entire back flared up red. The pediatrician suggested my niece now has a latex allergy and possible nickel allergy. Latex allergies can develop over time with multiple exposures.

Well over two years ago, Carter's and the CPSC issued an advisory to parents about tagless or heat transfer labels located in the back neck of their clothing. They had received reports that the labels were causing allergic reactions and irritation. The advisory stated that the reported incidents were rare and a small percentage of the thousands of units produced. The affected product was primarily the Fall 2007 line. This means the product was manufactured early 2007 or late 2006.

It is difficult to know what ingredient in the labels is causing the reaction. Some have suggested formaldehyde. Others suggest it is the pthalates, which exist at a far higher concentration than other products. It is puzzling that with documented problems that neither Carter's or the CPSC have done a more thorough investigation. Instead the CPSC is bogged down with debates over the amount of lead in the brass ball of an ink pen or whether a bicycle manufacture can use lead in a tire valve. Surely the CPSIA, that ultimate guardian of children's safety would not have allowed this kind of problem to persist. One has to wonder where the consumer protection groups are on this? Why aren't they making a big stink?

You would think that a product that proved to be a problem would have been resolved by now. No. Carter's released their Spring 2009 line with a reformulated ink and label style - two years later. Because there was no product recall there is an untold amount of product still floating around. (Even with a recall, there would still be a lot of product out there because recalls rarely recover 100% of sold merchandise).

You can accuse me of hysteria or panic if you choose. I'm most guilty of cynicism about federal regulations that don't seem to actually accomplish intended goals. But the reason I am writing this is because my youngest niece suffered a reaction to a tagless label. I was even more incensed when I saw this picture.

You see this label does not even belong to Carter's. It's an Arizona Jean Co. bodysuit, a private label product for JCPenny. The brown around the label is actually my niece's blood! You can see the rash on her back below.

My sister purchased the bodysuit in Fall of 2008 in anticipation of need later in 2009. It wasn't after her baby had worn the bodysuit a few times that she realized the source of the problem. My sister reported the problem to JCPenny and was told she would be refunded her money and receive new product. She was also advised to report the problem to the CPSC herself (which she is doing). Huh? Since I have worked on private label programs for JCPenny, I know how meticulous and thorough they are with safety. This is surprising to say the least.

This is all rather troubling. Doesn't the CPSC require companies to report safety problems immediately? Of course the CPSC may receive a report but how long will it take for them to react, especially now? This problem illustrates how upside down the whole system has become*. We focus all of our energy in silly debates about ink pens, ban rhinestones with no bio-available lead and spend all of our time recalling toys with minuscule amounts of lead - all with no reported injuries. Compare that with the many reports of injuries related to these labels, and we get, well, nothing.

Spring 2009 is two years after the initial reports. Why so long? Why not switch to traditional labeling in the interim? Carter's claims they went tagless to improve the comfort factor - no scratchy label. Well, a scratchy label can be cut out and the problem removed. A tagless label on a baby's bodysuit is not easily removed and must be thrown out. After all this, I think I prefer traditional labels.

*In fairness, the CPSC is working on a consumer database to report incidents as required by law. They are in the process of comment gathering and workshops. Problems can be reported now, but the information required by the CPSIA is not publicly available. If anything, the CPSC should look at a complete overhaul of their entire website which is a disorganized mess. But that is an argument for another day.

Well over two years ago, Carter's and the CPSC issued an advisory to parents about tagless or heat transfer labels located in the back neck of their clothing. They had received reports that the labels were causing allergic reactions and irritation. The advisory stated that the reported incidents were rare and a small percentage of the thousands of units produced. The affected product was primarily the Fall 2007 line. This means the product was manufactured early 2007 or late 2006.

It is difficult to know what ingredient in the labels is causing the reaction. Some have suggested formaldehyde. Others suggest it is the pthalates, which exist at a far higher concentration than other products. It is puzzling that with documented problems that neither Carter's or the CPSC have done a more thorough investigation. Instead the CPSC is bogged down with debates over the amount of lead in the brass ball of an ink pen or whether a bicycle manufacture can use lead in a tire valve. Surely the CPSIA, that ultimate guardian of children's safety would not have allowed this kind of problem to persist. One has to wonder where the consumer protection groups are on this? Why aren't they making a big stink?

You would think that a product that proved to be a problem would have been resolved by now. No. Carter's released their Spring 2009 line with a reformulated ink and label style - two years later. Because there was no product recall there is an untold amount of product still floating around. (Even with a recall, there would still be a lot of product out there because recalls rarely recover 100% of sold merchandise).

You can accuse me of hysteria or panic if you choose. I'm most guilty of cynicism about federal regulations that don't seem to actually accomplish intended goals. But the reason I am writing this is because my youngest niece suffered a reaction to a tagless label. I was even more incensed when I saw this picture.

You see this label does not even belong to Carter's. It's an Arizona Jean Co. bodysuit, a private label product for JCPenny. The brown around the label is actually my niece's blood! You can see the rash on her back below.

My sister purchased the bodysuit in Fall of 2008 in anticipation of need later in 2009. It wasn't after her baby had worn the bodysuit a few times that she realized the source of the problem. My sister reported the problem to JCPenny and was told she would be refunded her money and receive new product. She was also advised to report the problem to the CPSC herself (which she is doing). Huh? Since I have worked on private label programs for JCPenny, I know how meticulous and thorough they are with safety. This is surprising to say the least.

This is all rather troubling. Doesn't the CPSC require companies to report safety problems immediately? Of course the CPSC may receive a report but how long will it take for them to react, especially now? This problem illustrates how upside down the whole system has become*. We focus all of our energy in silly debates about ink pens, ban rhinestones with no bio-available lead and spend all of our time recalling toys with minuscule amounts of lead - all with no reported injuries. Compare that with the many reports of injuries related to these labels, and we get, well, nothing.

Spring 2009 is two years after the initial reports. Why so long? Why not switch to traditional labeling in the interim? Carter's claims they went tagless to improve the comfort factor - no scratchy label. Well, a scratchy label can be cut out and the problem removed. A tagless label on a baby's bodysuit is not easily removed and must be thrown out. After all this, I think I prefer traditional labels.

*In fairness, the CPSC is working on a consumer database to report incidents as required by law. They are in the process of comment gathering and workshops. Problems can be reported now, but the information required by the CPSIA is not publicly available. If anything, the CPSC should look at a complete overhaul of their entire website which is a disorganized mess. But that is an argument for another day.

August 12, 2009

A Warning on Labeling Bamboo Textiles

Bamboo fabric has long been considered a miracle green fabric. It is super soft, absorbent, biodegradable, and considered antimicrobial. It is true that bamboo is considered an eco friendly plant because it can be grown quickly without the use of chemicals. Many products have been produced from bamboo - from floors to textiles. Some of the eco friendly claims have come under scrutiny, especially bamboo textiles.

Bamboo textiles are produced by two methods. One can be considered sort of green and the other not. With the first method, bamboo stalks are crushed and broken down with enzymes and then combed out. The second utilizes harsh chemicals to break down the bamboo stalks into pulp which is extruded by spinnerets. This second method is the same process in which Rayon fabrics are manufactured.

You can bet that the majority of the bamboo fabrics on the market are manufactured by the second method. Because of this, the FTC has declared that bamboo fabrics must be labeled Rayon with the qualifier from bamboo. While this is a controversial position taken by the FTC, it is more accurate due to the actual processes being used. The FTC has clamped down on some companies claiming their bamboo textiles are "green". The charges include falsely advertising some of the more outlandish claims of being antimicrobial and biodegradable.

Anyway, be careful of how you label bamboo. The FTC has further guidance on how to deal with bamboo.

Labels:

Bamboo,

Care/Content Tags,

Eco Friendly,

Fabric,

FTC,

Labels,

Rayon,

Regulations,

Sustainable,

The Business End

July 07, 2009

Wedding Dress Care-Content Labeling

This article now has a follow-up blog entry with some corrections and additional opinions. Your comments are welcome, but hateful or spammy comments will be deleted.

As I was working on the alterations for this wedding dress, I wanted to see other dresses by this designer/maker. Perhaps the sleeve pattern shaping was intentional and not a mistake? Perhaps the problem is consistently found in other styles? I had no idea who the designer was, only where the dress was purchased. The dress was not in the store's web catalog and the only label in the dress was not helpful. The dress was missing a brand label and had no RN number. Further, the care instructions were rather bizarre/interesting (click on the picture for a closer view). I googled the style number and came up empty.

At a minimum, the dress should have had an RN number on the label. You can search an FTC database to find out the manufacturer of an apparel item. Wedding dress manufacturers/bridal shops have been fined in the past for failing to disclose or intentionally removing this information. Alterationists may remove the labels after purchase but should give them to the bride (links to come later as the FTC website was having problems when I wrote this).

The label states:

100% polyester

Do not dryclean

Spot clean ONLY

Use cold water and

mild soap

Made in China

See reverse for care

----------------------

Do not spray Alcohol

based product directly

on gown such as Perfume,

Hairspray....etc. This will

damage beadworks and

embroiderie designs made of

Rayon, Nylon, and other

synthetic materials.

I found the care instructions rather hilarious. How many of you spot cleaned your wedding dress with only cold water and mild soap? The fabrics themselves probably could be dry cleaned or even hand washed (though that may be more work). The beads will probably dissolve in the dry cleaning solvents, so thus the "do not dry clean" instructions. But, if you can find a reputable dry cleaner who will clean the dress and avoid the beads, then go ahead and have the dress dry cleaned. Otherwise, hand wash the dress. BTW, there were no further care instructions on the back of the label. Many wedding dresses are currently manufactured in China, which may explain the poorly written tag.

The extra instructions are interesting. I suppose it is possible that perfume or hairspray may damage the beads. Though the bride would probably need to be drenched in it before the beads dissolved. Sure would like to put those beads to the test....

The label should have been written to say:

100% Polyester

Hand wash or

Spot clean

in cold water with

mild soap. Hang to

dry. Do not bleach,

Do not iron.

Made in China

RN12345 ( ------ Made up)

---------------------

Avoid the use of

Alcohol based products

such as hairspray,

perfume, etc., as these

may damage the dress.

And of course, the care instructions should be thoroughly tested by the manufacturer. Good industry practice (and the government) dictate that a manufacturer should have a reasonable basis for the cleaning instructions. This means actual test data recorded and stored with the manufacturer. At this point in time, manufacturers (except children's clothing manufacturers) can do their own in-house wash testing. Children's clothing manufacturers will have to have it done by a certified laboratory. Wash testing is not specifically mentioned in the CPSIA, but it does imply that ANY testing will have to be done in a certified lab.

Labels:

Care/Content Tags,

Cleaning,

CPSC,

CPSIA,

Dry cleaning,

Fabric,

FTC,

Labels,

Testing,

Wash testing,

Wedding dress

April 10, 2007

Country of Origin labeling examples

One comment from a reader on my Designers hate care/content labeling blog made a good point. Labels can be very irritating to the end user. Rest assured, it is perfectly legal to remove labels after purchase. The size and placement of labels should concern designers because it is all related to your brand. I searched through my stash to find examples of how other designers deal with US labeling requirements. I could not find any pieces that did not comply with labeling requirements. I guess I tend to buy product that is honest in their labeling. Clothing that leave off labels or fail to place them properly says something about your company (and it isn't good IMO). All of these examples have the labels correctly placed near the back neck with the country of origin prominently displayed.

Country of origin as part of the brand label. This is also one of my rare Made in USA pieces.

Country of origin as part of the brand label. This is also one of my rare Made in USA pieces.

A size tag/country of origin label stitched to the bottom of the brand label.

A size tag/country of origin label stitched to the bottom of the brand label.

A separate size/country of origin label placed next to the brand label.

A separate size/country of origin label placed next to the brand label.

This is a typical example. The brand label is stacked on top of the care/content tag. The country of origin clearly shows below the brand tag.

Country of origin as part of the brand label. This is also one of my rare Made in USA pieces.

Country of origin as part of the brand label. This is also one of my rare Made in USA pieces. A size tag/country of origin label stitched to the bottom of the brand label.

A size tag/country of origin label stitched to the bottom of the brand label. A separate size/country of origin label placed next to the brand label.

A separate size/country of origin label placed next to the brand label.

This is a typical example. The brand label is stacked on top of the care/content tag. The country of origin clearly shows below the brand tag.

Labels:

Analysis,

Care/Content Tags,

FTC,

Labels,

Regulations,

Technical Design

April 03, 2007

Designers hate care/content labels

I was shopping a week ago or so in one of my favorite discount stores, Ross Dress for Less. As I was working my way through the blouse rack, I noticed a significant problem with most of the blouses on the rack. The blouses did not have a proper notification of country of origin (I would of counted how many were not in compliance, but DH was getting bored). According to FTC recommendations, items with a neckline must have a label stating the country of origin at or near the inside center back neck. These blouses only had a small brand label. A separate care label was attached to a side seam, with country of origin disclosed there.

I have read the FTC recommendations dozens of times and I am always surprised of the amount of non-compliance that exists in the marketplace. Some companies must be ignoring (or are ignorant) of the requirement. Further, many of the items in this store are imports. This means they had to pass custom inspections. I don't get it.

I follow the rules, and yet I have seen many designers insist they don't have to place a label at the back neck. After all, it is ugly and takes away from hanger appeal. If no one else is doing it, why should they. Children's clothing poses an additional challenge - there is only so much space in the back neck.

Here is a picture of an infant girl's dress. The label is correctly placed near the back neck. This placement requirement creates consistency across a broad range of products. Customers can know where to find basic product information. If I wanted to purchase Made in USA product, then it would be simple to find out.

Here is a picture of an infant girl's dress. The label is correctly placed near the back neck. This placement requirement creates consistency across a broad range of products. Customers can know where to find basic product information. If I wanted to purchase Made in USA product, then it would be simple to find out.

It is only required that country of origin information be placed in a reasonable, accessible place (generally the back neck in items with a neck). Care information may be placed in a side seam, or elsewhere. Generally, children's items have the information combined on one tag. Think about your customers. Do you really want them to have to fish through an entire item of clothing to see where it was made and how it should be cleaned?

I have read the FTC recommendations dozens of times and I am always surprised of the amount of non-compliance that exists in the marketplace. Some companies must be ignoring (or are ignorant) of the requirement. Further, many of the items in this store are imports. This means they had to pass custom inspections. I don't get it.

I follow the rules, and yet I have seen many designers insist they don't have to place a label at the back neck. After all, it is ugly and takes away from hanger appeal. If no one else is doing it, why should they. Children's clothing poses an additional challenge - there is only so much space in the back neck.

Here is a picture of an infant girl's dress. The label is correctly placed near the back neck. This placement requirement creates consistency across a broad range of products. Customers can know where to find basic product information. If I wanted to purchase Made in USA product, then it would be simple to find out.

Here is a picture of an infant girl's dress. The label is correctly placed near the back neck. This placement requirement creates consistency across a broad range of products. Customers can know where to find basic product information. If I wanted to purchase Made in USA product, then it would be simple to find out.It is only required that country of origin information be placed in a reasonable, accessible place (generally the back neck in items with a neck). Care information may be placed in a side seam, or elsewhere. Generally, children's items have the information combined on one tag. Think about your customers. Do you really want them to have to fish through an entire item of clothing to see where it was made and how it should be cleaned?

February 13, 2007

Another Care/Content Label Example

It's time to look at another care/content label. These labels were found in a 12M knit top that is part of a two-piece set.

It's time to look at another care/content label. These labels were found in a 12M knit top that is part of a two-piece set.The first thing that caught my eye was the placement of the country of origin. Country of origin information must be placed so that it can be seen without flipping the label over. Nothing can cover the country of origin information, like a brand label. It should be placed in an easily accessible area, like the back neck or waistband.

Another interesting observation is the style number and lot number information included on the front of the label. The lot number probably refers to the production lot and corresponds to a date of manufacture (lot numbers are unique to each company, so it could mean almost anything). Generally, this information is found elsewhere, like the reverse of the tag or even on a separate tag stuck into a side seam. It is certainly not anything that a customer is going to care about. I like the inclusion of this info for easy back-tracking, but it should be placed elsewhere.

This tag contains both an RN and CA numbers. The CA number is the Canadian equivalent to the the US RN number. This product was most likely sold in both Canada and the US, thus the need for two numbers.

The reverse side of the label contains all relevant information. My only nit-pick is the overall formatting. I generally prefer the content information first, followed by the care info. This label is just the opposite. Further, the content information is a different font, font size, and right-aligned compared to the care instructions. It makes the whole reverse side appear sloppy.

My final nit-pick is that the label should say "2 piece set" somewhere. Inevitably, the two pieces will be separated. This helps the shipping and store employees on the retail end realize there should be two pieces on the hanger.

Labels:

Analysis,

Care/Content Tags,

FTC,

Labels,

Regulations,

Technical Design,

Tracking

January 02, 2007

Country of origin labeling for clothing

I couldn't resist writing a blog about this particular care/content tag found in a t-shirt that was a Christmas present. This is perhaps one of the worst labels I have seen in a long time. In fact, I believe it was purposely written to make it look like it was made in the USA.

The maker of this shirt did a few things right. The tag clearly states the content of 100% Cotton and it was placed at the back of the neck. Unfortunately, this is the only thing they did right.

The first obvious problem is the different font sizes. Notice how the words Dominican Republic are smaller than anything else. You might think they made those words smaller so they could fit on one line of the tag. But the placement of all the words could make a consumer believe the shirt was actually made in the USA. I did when I first looked at it. Further, the addition of the phrase "of USA Fabric" is extraneous. It should simply state, "Made in Dominican Republic" period.

This tag would not be acceptable by FTC guidelines. When writing a tag, all of the words on the tag should be of a uniform, legible font size. The tag would be rejected for more than the font size issue. This particular shirt is missing a care tag and manufacturer identification. The content tag does not need to include the manufacturers name or RN number. That information should be included on the care tag and/or other packaging. It would be impossible to track down who manufactured this shirt. The FTC could go after the retailer, in this case.

This kind of thing should have been caught when the items were brought into the US. I am, however, not surprised to see it was missed.

Labels:

Care/Content Tags,

CPSC,

Manufacturing,

Regulations,

Technical Design,

Training

December 12, 2006

Care/Content Label Example in Two Languages

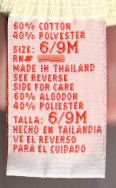

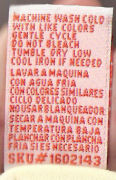

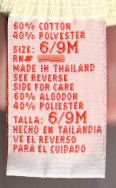

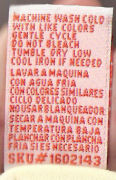

Writing a care/content label can be difficult. There are government regulations, department store requirements, company budgets, and a lot of info to fit in a small space. Every company comes up with creative solutions. If I get stuck on how to write a care label, I go shopping (or at least my closet)! I have seen a lot of good examples and poor examples of how to write a care/content label. I may blog about care/content labels in the real world on a semi-regular basis. New designers need a better understanding of labeling requirements. Since my blog focuses on children's clothing, I will try to pull labels from children's clothing. Children's clothing presents some difficulty when creating a care/content label.

In my first example, I pulled a label from a cotton t-shirt with a screen print, sized 6-9M. I smudged out the RN# because I want to keep the manufacturer anonymous. I apologize for the pictures being a bit fuzzy - labels are harder to scan than I thought. I will do better on my next blog. The front of the label is on the left, the back is on the right.

In my first example, I pulled a label from a cotton t-shirt with a screen print, sized 6-9M. I smudged out the RN# because I want to keep the manufacturer anonymous. I apologize for the pictures being a bit fuzzy - labels are harder to scan than I thought. I will do better on my next blog. The front of the label is on the left, the back is on the right.

The first thing that caught my eye about this label is the colors. The label is a folded woven, satin label with orange lettering. This kind of label is a bit more expensive than a regular printed label. I wouldn't have expected this style in an ordinary t-shirt, especially one that came from a major discounter. The label is in English and Spanish. This is a typical requirement for department and chain stores.

I had previously blogged about keeping track of production by recording some kind of information on the label. This label has a SKU # on the bottom of the reverse side of the label. It is a little unusual to see a SKU number, but it does occur.

The only thing I would change is the repetition of the size information. The English/Spanish could be combined on one line: "Size/Talla 6/9M. It is also preferred to keep the font size for all of the characters and numbers on the tag the same size.

November 08, 2006

Tracking production with a numbering system

Every now and then it becomes necessary to know when and where previous production was made. This issue may come up when doing quality auditing or reviewing customer returns. If there is no tracking information included with a garment, it will be impossible to backtrack through manufacturing to correct problems. If you manufacture the same item multiple times and/or in different places, a tracking system becomes absolutely essential.

The best way to backtrack is to include either a cut number or modified style number on a care/content tag. Modifying a style number is the simplest method and may be best if you work with only a few factories and few cuts. Say you are cutting style #1001 and sending it to Bob's Contract Sewing, your style # could read BCS1001. This method works well if you cut one style at a few different places, one time.

If you manufacture t-shirts, you may need a more complex cut number assignment. Let's say your t-shirts are cut every month at three different locations. In this case, you will need to devise a cut numbering system. Start by assigning a number for each factory. Your cut number should incorporate the style number, factory, date, and some number. If we are working with style #1001, at factory 3, for the month of November, and this is the first cut of the month, the number may look something like this: 1001-03-1106-01. I added hyphens in this example so you could see each number designation. If this number is too long, some people separate the style number from the cut number:

Style: 1001

Cut: 3110601

It is not necessary to place the style and cut numbers on the care/content labels, but that is the most convenient place. These numbers are frequently placed at the bottom of the care/content tag just before the country of origin. Sometimes it is found on the reverse side of the labels or even on a separate label stuck into a side seam. Here is one example of including it on a care/content tag:

The best way to backtrack is to include either a cut number or modified style number on a care/content tag. Modifying a style number is the simplest method and may be best if you work with only a few factories and few cuts. Say you are cutting style #1001 and sending it to Bob's Contract Sewing, your style # could read BCS1001. This method works well if you cut one style at a few different places, one time.

If you manufacture t-shirts, you may need a more complex cut number assignment. Let's say your t-shirts are cut every month at three different locations. In this case, you will need to devise a cut numbering system. Start by assigning a number for each factory. Your cut number should incorporate the style number, factory, date, and some number. If we are working with style #1001, at factory 3, for the month of November, and this is the first cut of the month, the number may look something like this: 1001-03-1106-01. I added hyphens in this example so you could see each number designation. If this number is too long, some people separate the style number from the cut number:

Style: 1001

Cut: 3110601

It is not necessary to place the style and cut numbers on the care/content labels, but that is the most convenient place. These numbers are frequently placed at the bottom of the care/content tag just before the country of origin. Sometimes it is found on the reverse side of the labels or even on a separate label stuck into a side seam. Here is one example of including it on a care/content tag:

100% Cotton

Machine wash cold,

use non-chlorine

bleach as needed,

tumble dry,

low iron.

Size: 9M

Style: 1001

Cut: 3110601

Made in USA

Machine wash cold,

use non-chlorine

bleach as needed,

tumble dry,

low iron.

Size: 9M

Style: 1001

Cut: 3110601

Made in USA

I have seen a variety of cut numbering systems, so feel free to devise whatever method will work for you. Make sure to keep some kind of log in a spreadsheet or notebook. You can track what numbers have been used, what cuts have been sent and returned, etc. The most useful reason for assigning a cut number is to track problems back to a factory. If a customer returns something because a seam opened up, you can go back to the factory and alert them to this quality issue. Some factories keep very careful records of the operator and operation performed on a cut, so you can imagine how far you can back track and correct problems.

If you would like more examples, check out product in any major department store. You will see they require their vendors to incorporate a cut numbering system. It makes for a good industry practice.

If you would like more examples, check out product in any major department store. You will see they require their vendors to incorporate a cut numbering system. It makes for a good industry practice.

Labels:

Care/Content Tags,

Manufacturing,

Systems,

Tracking

July 02, 2006

How to create a care, content and sizing tag for clothing

|

| Roland Russwurm [CC BY-SA 4.0 (https://creativecommons.org/licenses/by-sa/4.0)]* |

Deciding what information to include on a hang tag or a garment's care and content tag can be frustrating. There are certain legal requirements for care and content tags of items sold in the United States and that can be found at the Federal Trade Commission website.

Let's start with the care/content tags. Let's assume that you have complied with all of the legal requirements. What else should go on your care and content tag? The answer is as little as possible. The tag has a finite amount of space, and it must be legible. But there is some critical information that will help the consumer pick just the right size.

Sizing information is one of those things that should be on the tag. For children's clothing it helps to put not only the size but also the weight. It would be nice to also include the height, but I rarely see this done in the US. I have seen the sizing information arranged different ways. For example, it could read like this: 0-3M (7-12lb).

This additional bit of information is very important to consumers. Even though we use a size system that designates an age, children come in all shapes in sizes at each stage of life. Ever hear of a newborn weighing 9lb? A newborn weighing 9lb at birth will weigh 12-15lb at about 3mo, and quickly move into 6mo clothing. Including the weight on a tag helps take out the guess work for the consumer. And don't forget every children's company breaks their sizing down differently. A 3mo outfit from one company will not be the same size as a 3mo outfit from another.

If there isn't room on a care/content tag for additional information, then it is helpful to include it on a hangtag. BabyGap has sizing information available on a card that is the size of a business card and it can be stuck in a wallet. What a great service for the customer! Not to mention, it probably helps reduce returns.

Most moms know the height and weight of their baby. They are given this information when they visit their pediatrician. The doctor will compare the baby's height and weight with a growth chart to make sure the baby is growing properly

If you have an online store, a size chart that includes basic height and weight information will greatly help your customers.

*Photo Credit

Subscribe to:

Comments (Atom)