Q: Is there an industry standard for Tech Packs?

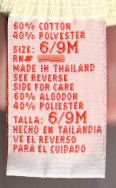

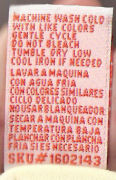

No, but there is industry expected information. There are several tech pack templates and forms available for purchase on the Internet, and they are all a bit different in presentation. Generally, those tech packs seek the same information. A Tech Pack contains any and all information needed to manufacture your product. This information includes a cover page, technical drawings, cutting specs, labels, etc. The forms included in my Tech Pack allow for a lot of flexibility so it doesn't matter if you are manufacturing clothing, bags or tents.

Q: Does a Tech Pack include a cutting spec?

I have seen some statements that imply a cutting spec is usually not included in a tech pack. That has not been my experience. If a cutting spec is needed to make your product, then it should be included in a tech pack.

Q: What forms do I send to a contractor?

Only the forms that are needed for the work contracted. It is possible to hire a contractor that can do everything from product development to cutting, sewing, finishing and shipping. Usually, a sewing contractor is hired to do cutting and sewing. In that case they only need a cover sheet, style sheet/cutting spec, bill of materials, colorways (if needed), labels, swatches, and anything else needed to complete the work. Forms that contain proprietary info are for your own in-house use, such as a cost analysis.

Q: What is the difference between a Cost Analysis and a Bill of Materials?

A Bill of Materials contains a list of every input (fabric, trim, supplies) needed to manufacture your product. It does not contain pricing. This form can be used for ordering and inventory.

A Cost Analysis also contains a list of every input but also includes pricing and quantity. This form is used to figure the cost of manufacturing, sale price, and gross profit. This information is kept confidential.

Q: What else should my Tech Pack include?

A tech pack is usually just the paper work involved in product development. But if you are sending a tech pack to a sewing contractor, you should include a perfectly sewn sample and fabric and trim swatches. This is especially important if you are manufacturing overseas where there may be a language barrier. The sample will help clarify what you want when the contractor may not understand or read the tech pack. Swatches are also helpful if the contractor is also buying materials overseas.

Q: I don't draw well, do I have to include technical drawings?

Any drawing is better than no drawing. It is the primary way you will communicate with a technical designer and/or pattern maker. You can also hire people to create the drawings for you at reasonable cost.

Q: Can I customize The Simple Tech Pack?

Yes. Included in your purchase is a spreadsheet workbook version (Excel and LibreOffice Calc). You can add your company info and logo. You can also rearrange, rename information if you choose. The only caveat is that the forms are copyrighted and cannot be resold.

Q: I'm an indie pattern designer. Will this tech pack help me?

Yes. An indie pattern designer is very similar to a fashion designer. You will still need to develop a style, cutting spec, measurements, sewing instructions and grade rules. The cost analysis will help you price your product. The Simple Tech Pack can help you organize the information needed for your final product.

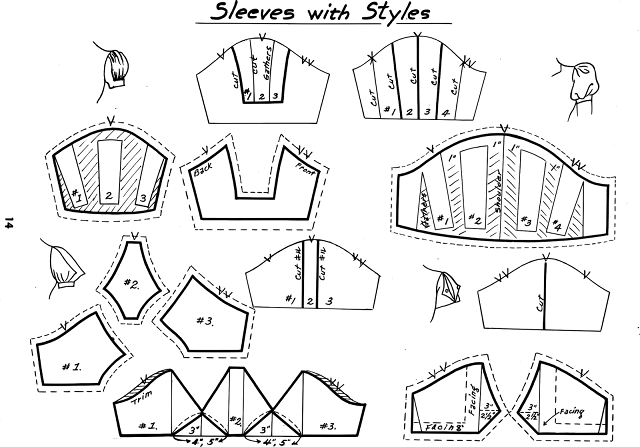

Q: Why does your Tech Pack have a Style Sheet instead of a simple cutting spec?

I created a combination form called a Style Sheet. This form contains both a technical drawing and a cutting spec. I have found it very useful in product development to include a technical drawing with the cutting spec as it travels through sampling. That way every person along the way has the same point of reference. It reduces both paperwork and questions.

Do you have any other questions? Please leave a comment and I'll answer your question in an upcoming blog post.