I received some great questions in my mail box the other day from a new childrenswear designer:

Is getting into children's wear a big business? I mean, can one be profitable? I see a lot of my friends who are women's wear designers just breakeven after all that hard work. I enjoy designing for kids and feel that it might be less competitive that women's wear so therefore one may be able to be a tad more profitable in this area?

Let me tackle these one at a time.

Is getting into children's wear a big business?

Yes. I won't take the time to find the numbers, but there is a lot of money to be made in children's apparel. Well known designers may start with women's wear, but they end with children's. It may seem they add a children's line as an afterthought, but that is also where the largest profit margins are. With a well established women's brand, it makes sense to extend it into children. Labor and material costs are less, but the prices can be as high as women's. Hollywood stars and well-meaning, new mothers launch their own children's line when they start a family. Then let's throw in cheap imports by the major chain stores. How is one supposed to compete with that!? If you don't fall into any of these categories, it can seem overwhelming! There is a lot of competition in children's clothing.

I mean, can one be profitable?

With all of the competition that already exists, this is a good question to ask. And it all depends on how you run your business. Any business is difficult. If you start a business, you are the one that bears the responsibility to make it successful. Often the hours you work will be longer and harder than a regular job. You will take your work home at night, lose your weekends, and may never really take a vacation. You do all of this in the hopes of making a profit (and maybe because you love it too).

The simple definition of a profit is to spend less money than you make. Even with the complexity of the fashion business, this simple definition remains true. At the end of the day (week, month), you must sit down and analyze your income vs. expenditures. If you are spending more than you make, you will not make a profit.

The real question here is "How do I make a profit?" This is a slightly more complex answer. There are a lot of variables, even in the childrenswear category. I have read business books and talked with many people in the fashion business. Here are some of the guidelines I have learned that I now use for my business:

1. Spend less than you make.

2. Avoid debt. Most small businesses will take out a small business loan or use savings to get started. Determine a plan to pay off your loans as soon as possible. A debt payment is less money earned in income.

3. Put a little into business savings and make a small charitable donation to your favorite organization (It will make you feel good, is tax deductible, and it just might help somebody). You can use your business savings for future equipment, expansion, and to cover lean times.

4. Try to deal on a cash basis as much as possible. If you are just starting out, you are not in a position to extend credit to anyone, nor to overextend your own credit situation. If you make a sale, try to get money as soon as delivery is made.

5. Plan carefully. More mistakes are made by not planning carefully. Kathleen Fasanella's book,

The Entrepreneur's Guide to Sewn Product Manufacturing explains how to manufacture your designs. If you follow each step of the process outlined in her book, then you will more likely succeed.

6. Keep growth under control. You may have received a $20,000 order, but unless you can fill it, don't do it. It may seem ludicrous to turn down such a large order. But if you take the order and don't fill, you can do a lot damage and may put yourself out of business. When you are ready to start taking such large orders, have everything in place beforehand.

7. Set goals. Why are you in business? Where do you want to go? These can be large and lofty or small and mundane. One of my goals is to be able to pay my bills and earn X amount of income. Another goal of mine is to provide X number of jobs to the local economy. Try to set goals that are realistic for the short term, but keep in mind the big ones.

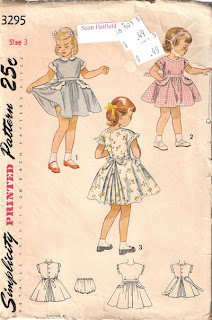

8. Stay focused. When starting out, it is best to focus on one category - like girl's dresses or boys outfits. Later, you can expand into related categories.

9. Ask for help (or hire it). It is easy to get overwhelmed. But believe it or not, there are many out there willing to help.

10. Enjoy what you do! If you love what you do, you are more likely to stick with it.

I see a lot of my friends who are women's wear designers just breakeven after all that hard work. I enjoy designing for kids and feel that it might be less competitive than women's wear so therefore one may be able to be a tad more profitable in this area?

The first few financial years of your business will either break even or run in the red. It is a simple fact of life. But if it has been longer than that, then I have to wonder if these designers are following any of the guidelines above. And really, it doesn't matter what you design, you must pay attention to the business end. At the end of the day, the numbers must make sense. Any category has an equal chance of success or failure. If you want to design kid's clothes, then go for it!

I hope these guidelines are helpful. They have proven to work for me. You can succeed in fashion and as Tim Gunn says, "Carry on!".