November 12, 2013

Adapting a block pattern into something else pt. 5 : Making the pocket pattern

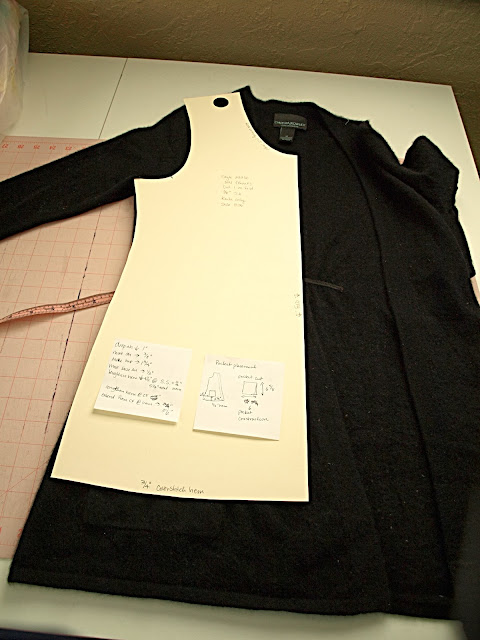

Here's a sneak peak of the first sample of my cardigan pattern. I'm fairly pleased with the results, though there are a couple of minor pattern modifications to make. So more about all that later.

For now, we need to finish up the pattern. The last two pieces to deal with are the pockets (shown above) and the elastic casing. I referenced my sweater to determine the pocket dimensions and placement, which is basically a rectangle. Pockets come in all sorts of shapes and sizes with varying amounts of functionality. Pockets should be proportional to the overall garment. They can be graded for larger or smaller sizes to maintain proper proportions. Pockets can be applied in various ways and include seam and hem allowances.

I wanted a very casual look to my pocket so I used a narrow 3-thread serger hem around all four sides and topstitched it on. This allowed the fabric at the top of the pocket to roll. This detail mimics the detail on my sweater. I didn't have a lot of confidence in producing a neat topstiched pocket in which the raw edges are turned under. This is partly due to the fabric and my machine. For a more structured pocket this fabric would need a fusible to help stabilize it.

Pocket placement is noted on the pattern piece by a drill hole. In a factory, an actual hole is drilled into the fabric. I have seen knits marked with a drill that also contained a marking medium such as a washable marker. In that case, the drill bit was like a needle. My pattern at home will contain a hole large enough for a chalk marking pencil to fit. Even though there are lines on the pattern pieces indicating placement, they are not transferred to the actual fabric. They are just there for clarity.

The elastic casing is just another rectangle large enough to cover the elastic. I think mine is about 1/2" x 8".

October 30, 2013

Adapting a block pattern into something else pt. 4 : how to create the neckband pattern piece

For review read part 1, 2, and 3 of this series.

All of the major pattern pieces are now done. Next up is to do the neckband, the elastic casing for the back waist, and pocket. These three pieces are just rectangles. In a CAD pattern making environment, I will make pattern pieces for all rectangles and squares. Pattern makers, graders, marker makers and cutters all handle these kinds of pieces a little bit different, so ask if you are not sure.

For me, working on a personal pattern in my own workspace I handle rectangle and square pieces one way. I figure out the dimensions and note them on my style sheet. You can do this for patterns* that will be used in a factory setting too, but you will need to create a cutting guide for any rectangular pieces which might be graded. For now noting the cut dimensions is sufficient.

Up to this point I haven't really needed to consider how the cardigan is to be constructed. The majority of the cardigan has rather simple construction that mimics the construction of the t-shirt. But the neckband can be constructed and attached in a number of different ways. I also have to consider the stretch factor along the back neck. Do I want a 3-piece neckband with seams at the shoulders or a 2-piece neckband with a seam at center back? How do I finish the neckband at the hemline? How wide? All these things have an influence on the dimensions of the cut piece.

I like to keep things simple so I opted for a 2-piece neckband with a seam at center back. A 3-piece band might be necessary if the fabric width is too narrow. A 1-piece neckband might be possible if the cardigan was smaller. Begin by measuring the front and back neckline of the cardigan patterns.

Now it is a matter of math. There really isn't a formula for this. It's just adding and subtracting.**

Neckband width = (front neck+back neck) - (front and back shoulder seam allowances + hem allowance) + seam allowance for center back + seam allowance at hemline - some stretch factor for the back neck.

Neckband length = 2 * (Desired finished width + seam allowance)

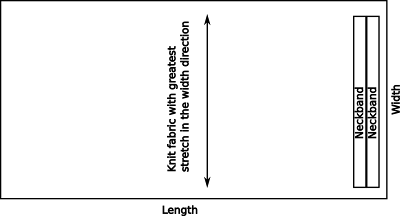

The neckband will be cut across the width of the goods like this:

Dimensions should be written as Length x Width. In this case the Length is the shorter measurement. My neckband pattern piece will then be something like:

5 x 30 inches

A CAD version or hard pattern will look something like this with a pattern number assigned instead of the words neckband:

You'll notice that I have two notches. The notch along the length (the narrow end) instructs the sewing machine operator to stitch the neckband pieces together at that end. The other notch along the width (long direction) is the match point between the neckband and the shoulder seam of the cardigan. This notch is necessary because I reduced the back neck to account for a stretch factor. This will help the back neck fit better rather than stand straight up.

Since I am just making one size and working at home I will draw a picture indicating the notch placement with a measurement along with the cut dimensions for the neckband.

*Managing rectangular and square pattern pieces is the subject for at least two additional blog posts! Yep, it's hard to believe but there is a lot to say on the subject....

**I do all this adding and subtracting right at the calculator.

All of the major pattern pieces are now done. Next up is to do the neckband, the elastic casing for the back waist, and pocket. These three pieces are just rectangles. In a CAD pattern making environment, I will make pattern pieces for all rectangles and squares. Pattern makers, graders, marker makers and cutters all handle these kinds of pieces a little bit different, so ask if you are not sure.

For me, working on a personal pattern in my own workspace I handle rectangle and square pieces one way. I figure out the dimensions and note them on my style sheet. You can do this for patterns* that will be used in a factory setting too, but you will need to create a cutting guide for any rectangular pieces which might be graded. For now noting the cut dimensions is sufficient.

Up to this point I haven't really needed to consider how the cardigan is to be constructed. The majority of the cardigan has rather simple construction that mimics the construction of the t-shirt. But the neckband can be constructed and attached in a number of different ways. I also have to consider the stretch factor along the back neck. Do I want a 3-piece neckband with seams at the shoulders or a 2-piece neckband with a seam at center back? How do I finish the neckband at the hemline? How wide? All these things have an influence on the dimensions of the cut piece.

I like to keep things simple so I opted for a 2-piece neckband with a seam at center back. A 3-piece band might be necessary if the fabric width is too narrow. A 1-piece neckband might be possible if the cardigan was smaller. Begin by measuring the front and back neckline of the cardigan patterns.

Now it is a matter of math. There really isn't a formula for this. It's just adding and subtracting.**

Neckband width = (front neck+back neck) - (front and back shoulder seam allowances + hem allowance) + seam allowance for center back + seam allowance at hemline - some stretch factor for the back neck.

Neckband length = 2 * (Desired finished width + seam allowance)

The neckband will be cut across the width of the goods like this:

Dimensions should be written as Length x Width. In this case the Length is the shorter measurement. My neckband pattern piece will then be something like:

5 x 30 inches

A CAD version or hard pattern will look something like this with a pattern number assigned instead of the words neckband:

You'll notice that I have two notches. The notch along the length (the narrow end) instructs the sewing machine operator to stitch the neckband pieces together at that end. The other notch along the width (long direction) is the match point between the neckband and the shoulder seam of the cardigan. This notch is necessary because I reduced the back neck to account for a stretch factor. This will help the back neck fit better rather than stand straight up.

Since I am just making one size and working at home I will draw a picture indicating the notch placement with a measurement along with the cut dimensions for the neckband.

*Managing rectangular and square pattern pieces is the subject for at least two additional blog posts! Yep, it's hard to believe but there is a lot to say on the subject....

**I do all this adding and subtracting right at the calculator.

October 25, 2013

Adapting a block pattern into something else pt. 3 : Modifying the t-shirt back pattern piece and sleeves to make the cardigan

For review read part 1 and 2 of this series.

Next up on my t-shirt block pattern transformation to a cardigan is to work on the pattern pieces for the back. I won't go into too much detail because there isn't much difference from the front.

Trace off the back and add the same length and width adjustments as the front. Extend the shoulder the same amount. Drop the armhole the same amount.

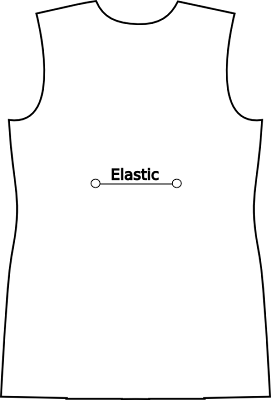

Next I add drill holes to indicate the elastic for the back waist. The elastic takes up some of the extra body ease in the back to make the cardigan appear more fitted. I didn't add additional design ease for extra fullness, just the same wearing ease as the front. If you draft your own pattern, you can add as much or as little as you want. I referenced the cardigan that I am knocking off for placement. In the picture below, the drill holes appear rather large, but that is just for clarity in the drawing. I'll take a picture of the finished pattern pieces when they are ready so you can see what it all looks like. In reality, the holes will only be large enough so a marking pen(cil) can make a mark.

I also modified my sleeve for length and width. My previous blog post on how to reduce/eliminate sleeve cap ease* should give you an idea of how to adjust the sleeve cap. Walk the sleeve cap along both the front and back armhole of the bodices pieces. The armscye should be longer than the sleeve cap. Note the difference and enlarge the sleeve cap so that it matches the armscye. You can do this by slashing and spreading. Do not add any sleeve cap ease. This is a myth perpetuated by pattern drafting manuals and others. You don't need it.

Finally, I referenced some cardigans in my closet to figure out how long to make the sleeve (plus hem) and how wide to make the wrist. I have a tendency to make my sleeves a little longer than necessary because long sleeves from off the rack stuff tend to be too short for me. Also, I worry about shrinkage. I will be pre-shrinking my knit fabric, but some knits will shrink with multiple washings. In any event, add the length you need for your sleeve.

Next up on my t-shirt block pattern transformation to a cardigan is to work on the pattern pieces for the back. I won't go into too much detail because there isn't much difference from the front.

Trace off the back and add the same length and width adjustments as the front. Extend the shoulder the same amount. Drop the armhole the same amount.

Next I add drill holes to indicate the elastic for the back waist. The elastic takes up some of the extra body ease in the back to make the cardigan appear more fitted. I didn't add additional design ease for extra fullness, just the same wearing ease as the front. If you draft your own pattern, you can add as much or as little as you want. I referenced the cardigan that I am knocking off for placement. In the picture below, the drill holes appear rather large, but that is just for clarity in the drawing. I'll take a picture of the finished pattern pieces when they are ready so you can see what it all looks like. In reality, the holes will only be large enough so a marking pen(cil) can make a mark.

I also modified my sleeve for length and width. My previous blog post on how to reduce/eliminate sleeve cap ease* should give you an idea of how to adjust the sleeve cap. Walk the sleeve cap along both the front and back armhole of the bodices pieces. The armscye should be longer than the sleeve cap. Note the difference and enlarge the sleeve cap so that it matches the armscye. You can do this by slashing and spreading. Do not add any sleeve cap ease. This is a myth perpetuated by pattern drafting manuals and others. You don't need it.

Finally, I referenced some cardigans in my closet to figure out how long to make the sleeve (plus hem) and how wide to make the wrist. I have a tendency to make my sleeves a little longer than necessary because long sleeves from off the rack stuff tend to be too short for me. Also, I worry about shrinkage. I will be pre-shrinking my knit fabric, but some knits will shrink with multiple washings. In any event, add the length you need for your sleeve.

October 17, 2013

Adapting a block pattern into something else pt. 2 : Pattern modifications to turn a t-shirt into a cardigan

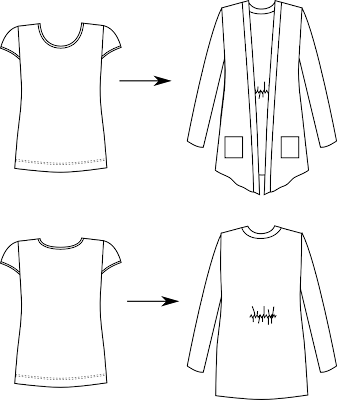

Rather than take pictures of my pattern making process of pencil on paper, I did up some line drawings. Just to refresh, I am tranforming a t-shirt block pattern into a knit cardigan.

I began by laying my t-shirt front pattern piece on to the cardigan that I'm knocking off and took notes on the differences. I had to keep a few things in mind as I compared the two. First, the t-shirt is close fitting with little extra wearing ease. The cardigan I'm knocking off was accidentally shrunk, so I need to add more wearing ease than is immediately apparent. A cardigan or jacket needs enough wearing ease that it is easy to put on and wear over other clothes. I can't tell you exactly how much wearing ease your pattern should have because it depends on what you prefer. Expect to add somewhere between 2-4 inches extra for this style.

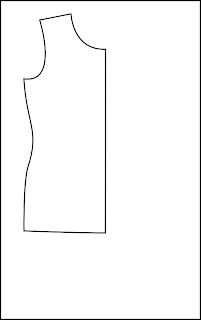

The first step is to trace off half of the front pattern.

Next, I lengthened the pattern piece based on my notes. My pattern piece includes the seam allowances and hem allowance. I don't remove the hem allowance, I just make a mental note and add the hem allowance to the length I've added.

To get the angled shape of the cardigan, I extend from the center front at the hemline and draw a line from the high point of the shoulder to the hem. Gravity will pull that point down and create the angle along with a bit of drape.

The greyed out area represents an area that is removed. On paper I scribble in any area to remind myself to ignore it. You could also erase it.

Next, I add in extra wearing ease by moving out the side seam, dropping the armhole, and extending the shoulder line. The extra ease added to the side seam should only be 1/4th the total ease added because we are only working on 1/4th of the total body circumference.

I'm still debating on how much wearing ease to add. I need to compare my body measurements to the pattern to make sure it is enough.

And this is a far as I've gotten so far. I need to make similar changes to the back pattern piece. I also haven't assigned pattern piece numbers yet. Blank forms for managing patterns are available in my Pattern Making bundle or in the book with complete instructions.

I began by laying my t-shirt front pattern piece on to the cardigan that I'm knocking off and took notes on the differences. I had to keep a few things in mind as I compared the two. First, the t-shirt is close fitting with little extra wearing ease. The cardigan I'm knocking off was accidentally shrunk, so I need to add more wearing ease than is immediately apparent. A cardigan or jacket needs enough wearing ease that it is easy to put on and wear over other clothes. I can't tell you exactly how much wearing ease your pattern should have because it depends on what you prefer. Expect to add somewhere between 2-4 inches extra for this style.

The first step is to trace off half of the front pattern.

Next, I lengthened the pattern piece based on my notes. My pattern piece includes the seam allowances and hem allowance. I don't remove the hem allowance, I just make a mental note and add the hem allowance to the length I've added.

To get the angled shape of the cardigan, I extend from the center front at the hemline and draw a line from the high point of the shoulder to the hem. Gravity will pull that point down and create the angle along with a bit of drape.

The greyed out area represents an area that is removed. On paper I scribble in any area to remind myself to ignore it. You could also erase it.

Next, I add in extra wearing ease by moving out the side seam, dropping the armhole, and extending the shoulder line. The extra ease added to the side seam should only be 1/4th the total ease added because we are only working on 1/4th of the total body circumference.

I'm still debating on how much wearing ease to add. I need to compare my body measurements to the pattern to make sure it is enough.

And this is a far as I've gotten so far. I need to make similar changes to the back pattern piece. I also haven't assigned pattern piece numbers yet. Blank forms for managing patterns are available in my Pattern Making bundle or in the book with complete instructions.

October 09, 2013

Adapting a block pattern into something else pt. 1 : Noting changes for the new style

A block pattern is a sewing pattern that has been proven. It is a pattern that has been trued, perfected and finished with seam allowances. The pattern has been sewn up and tested for fit. In other words, a block pattern just works. A block pattern becomes a part of a pattern file which can be used to make other patterns.

In the industry we rarely draft from scratch. Instead we modify existing patterns (or blocks) into something else. Some pattern making gurus talk about using slopers. Slopers are basic patterns drafted from body measurements and do not have seam allowances. Industry level pattern makers use block patterns, with seam allowances on, to make patterns for new styles*. It saves time.

It's easier than you might think to do this and this is just one example. I'm sure other pattern makers have their own procedures. My own procedures adapt to whatever it is I'm working on and whether I'm using CAD or traditional methods.

The problem:

I have this much loved cashmere sweater jacket. I snagged it off a sales rack a couple of years ago and I absolutely love the cut and fit. You know, the perfect layering piece, warm and soft for those cool days. I usually clean it by running it through the dryer using a Dryel kit. This last time was a disaster as I had left a piece of chocolate in a pocket. Chocolate ended up all over the sweater and everything else. So, I decided to run it through the hand wash cycle on my washer. That was a mistake. While the chocolate did come out, the sweater shrank. It shrunk just enough that I'm not sure I can wear it anymore. It made me very sad. And yes, I know better. I should have hand washed it.

The solution:

I always said that once this sweater was in pieces, I would make up a pattern to make a new one. So here it is. I recently finished up my t-shirt pattern, a block pattern ready to go. I began by carefully laying out the sweater and positioning the front t-shirt pattern on top. I then used scraps of paper to note the differences between the sweater and the pattern. You can see my notes in the picture above.

The notes** usually say something like: Move SH pt out 1/2" (left arrow) ; or Extend hem (down arrow) 3 inches. These notes are sometimes accompanied with drawings as needed. If I was working in CAD, I would just mentally note the differences and make the changes as as I went along. Since I'm drafting with pencil and paper, the notes are essential.

The next step is to trace off the t-shirt pattern and start applying the changes. More on that later.

*There are a lot of pattern making myths out there. I'm trying to keep this blog entry very focused but I'm happy to answer pattern making questions and myths in future posts. Please leave your question or comment below.

**These notes eventually find their way to my pattern piece catalog. I assign a pattern piece number, note the style/pattern piece that the new piece came from, and then tell what changes were applied and any other relevant details. Blank forms for managing patterns are available in my Pattern Making bundle or in the book with complete instructions.

Subscribe to:

Posts (Atom)